Benefits of LSR Overmolding

LSR injection molding is a cost-effective and versatile process used by manufacturers in a large number of industries and applications. From LSR overmolded handles to complex electronic assemblies ( ) , there are multiple reasons why rubber overmolding is a good choice for your project:

- Cost and time savings——By molding silicone directly onto a metal or plastic substrate, you’ll save the expense and time required to assemble a complex part manually. This can dramatically reduce your manufacturing costs and turnaround time, allowing you to get your product to market more economically.

- Design flexibility——LSR/thermoplastic injection molding is excellent for meeting the complex design requirements of the automotive and medical industries. Silicone rubber overmolding produces parts that are waterproof, airtight, and more resistant to shock and vibrations.

- Quality control——The LSR/plastic injection overmolding process offers high tolerance and strict quality control, making it suitable for use in any application where precision is required. Tayang can produce overmolded silicone rubber parts to your exact specifications, including devices that require manufacturing in a Class VII or Class VIII clean room.

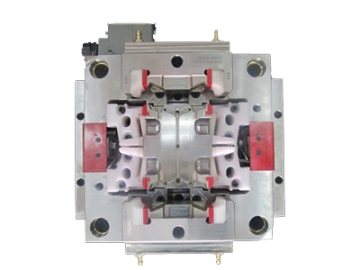

- How substrate material structure & physical properties changes when molds close? Parting line analysis is applied in Tayang.

- How substrate material structure & physical properties changes when injection & curing?The optimized pressure and temperature should be estimation and chosen advanced.

- How substrate position might changes when injection?It’s on the mold design review meeting checking list.

- How LSR flow goes when injection? The result of injection flow analysis software helps our judgment on mold design review meeting.

- What is the Difference Between Overmolding and True 2-Shot Molding?

Both overmolding and 2-Shot processes combine two substrates during the molding process to form one multi-substrate component. In LSR overmolding an LSR substrate is molded over a placed metal mass or a plastic part to produce the multi-substrate component, offering a wide array of substrate combinations. In a true, 2-shot molding process both materials are molded in the same process and machine with cavity-to-cavity alignment for superior bonding, and secure precise placement. Learn more about our 2-shot capabilities.

More - Advantages of Silicone Overmolding in TayangExperience

substrate mold amount in mass production(set) plastic 221 steel 37 others 15 Our overmolding projects have delivered to customer brands such as BOSE,Garmin,Apple,Samsung.More