Sodium Carbonate Industry

Valve in Sodium Carbonate Industry

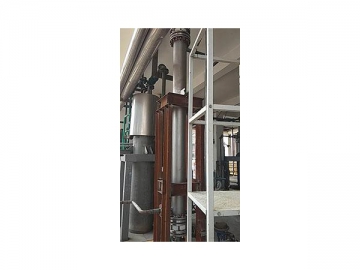

For sodium carbonate industry, difficulty in cutting off and controlling fluid caused by leakage is a knotty problem.

Common Problems

1. When the carbonizing tower is being heated, mother liquid will spill out due to the high temperature. To avoid the corrosion to the equipment caused by leakage, the blind disks shall be installed on the tower, which increases the labor intensity of the workers.

2. During the overhaul of pump AII, hot alkali liquid pump, as well as the pump for transmitting ammonium salt water treated with carbon dioxide, the operation of the system shall be stopped, which will affects the productivity.

3. Medium leakage will increase the difficulty in workshop management. The slurry leaked requires frequent cleaning. Besides heavy workload, environment will be polluted.

4. Additionally, production management will be affected by the failure in cutting off fluid, or the difficulty in operating the valve (such as globe valve for slurry control), caused by scale formation.

5. Frequent overhaul and replacement of valve will lead to more medium leakage.

Troubled by the inconvenience, staff responsible for production management, equipment operation and maintenance of the sodium carbonate industry have tried everything to avoid medium leakage. Moreover, they also need to conquer the problems caused by scale formation, blocking and erosion.

Quanshun has cooperated with sodium carbonate companies for many years. Our product improvement is conducted based on practical situation. The valve we can offer for sodium carbonate company include half ball valve, globe valve for sodium hydrate, etc.

Applications

- Stainless steel half ball valve-carbonizing tower

- Barrel I for mother ammoniacal liquid