Vacuum Casting

Request a Quote

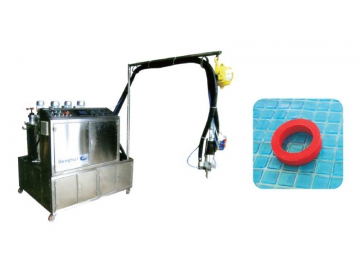

We have a vacuum casting machine to manufacture the prototypes for our customers via a vacuum casting technique.

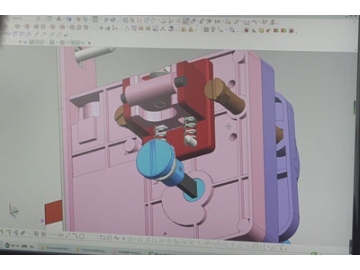

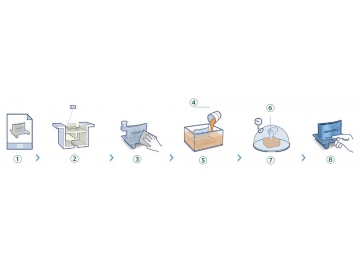

The main model is created using 3D printing. Next, a silicone mold is obtained after grinding the main model manually. Mix the raw materials and add them to the mold through vacuum bell jar. It takes time for the casting to be cured before removing it. The silicone mold can be reused multiple times and has limited lifespan. However, identical models can be obtained each time before its usage exceeds the lifespan of the mold.

① 3D file;

② Master built in Mammoth Stereolithography;

③ Thorough master finish;

④ Silicone;

⑤ Mold making;

⑥ PU(polyurethane);

⑦ Casting under vacuum;

⑧ Part finishing

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos