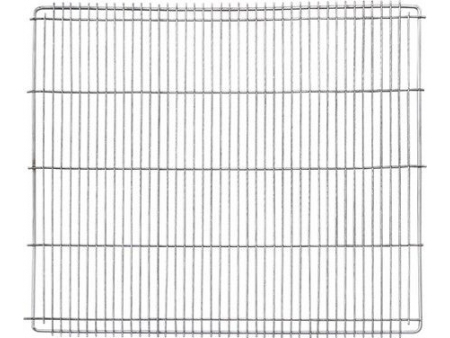

The wire shelf & rack welding line is a fully automated system crafted for carbon steel or stainless steel shelf manufacturing. This wire shelf production line is comprised of several machines including wire straightening and cutting machine, frame bending machine, butt welding machine, and automatic multi-head mesh welding machine.

Designed with flexibility in mind, this welding equipment offers customization options to meet specific customer needs. Clients can opt for either a fully-automatic type or a semi-automatic type, depending on their requirements. Additionally, we provide the option to tailor the equipment based on efficiency preferences, ensuring a seamless integration into diverse manufacturing environments.

Wire Shelf & Rack Welding Line

- Material: stainless steel, carbon steel, galvanized steel

- Wire diameter: 2-8mm (round) or 12x3mm (flat)

- Mesh width: 500-1000mm (customizable)

- Mesh length: 500-1500mm (customizable)

- Wire straightening and cutting

- Straight wires bent into square shape

- Butt welding for steel wire frame

- Reinforcing bars attached to the wire frame

- Weld the cross wires onto the frame

- Edge trimming of the wire frame

-

Steel wire straightening & cutting machine

Steel wire straightening & cutting machineThe machine is designed for the straightening and cutting of steel wire. Simply input the desired length, and the machine will automatically execute the cutting process.

- Applicable wire diameter: 1.1-1.5mm, 2-4mm, 5-7mm

- Length: 50-5000mm

- Speed: 80m-120m/min

- Precision: ±0.5mm

-

Steel wire flattening, straightening & cutting machine

Steel wire flattening, straightening & cutting machineThis equipment is used for flattening and straightening cutting of wires, which can press round wires into square wires and cut them into corresponding lengths as required.

- Wire diameter: 10x3mm, 12x3mm

- Length: 50-5000mm

- Speed: 8-12m/minin

- Accuracy: ±2mm

-

Steel wire bending machine

Steel wire bending machineThis equipment is used to bend straight wire into a box shape, and can bend 2-4 wires at a time.

- Size: 2-8mm for round wire; 10x3mm or 12x3mm for flat wire

- Length: 2000mm (customizable)

- Bending system: hydraulic

-

Butt welding machine

Butt welding machineT-butt welding for welding wire frame and reinforced bars

- Wire diameter: 3-12mm

- Power: 50-150KVA

- Power supply: AC, medium frequency

-

2D/3D wire bending machine

2D/3D wire bending machineThe equipment is designed to bend wires with varied diameters and shapes. Automated production of flat wires can be achieved using 2D bending machines, while 3D bending machines are employed for the fully automated production of three-dimensional wires.

- Wire diameter: 2-6mm, 3-8mm, 5-12mm

- Number of axes: 2 axis, 7 axis

- Bending system: hydraulic

-

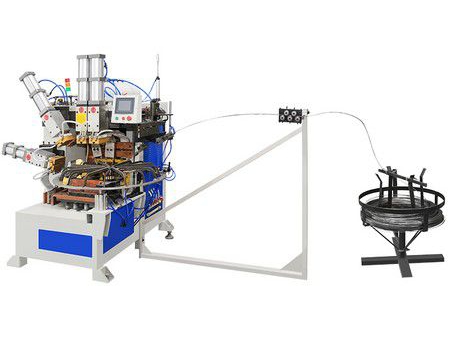

Automatic wire mesh panel welding machine

Automatic wire mesh panel welding machineCustomization options are available for both fully automatic production lines and semi-automatic welding machines, tailored to meet the specific requirements of customers. The equipment can be modified based on individual preferences, ensuring flexibility in design and functionality. Additionally, customization is offered to align with the efficiency standards specified by the customer, allowing for a personalized and optimized solution that meets their unique production needs.

- Automatic wire feeding: optional

- Wire diameter: 2-8mm

- Size: 500-1200mm (customizable)

- Automatic wiring: optional

- Welding head: 1-20pcs (choose according to the width of the mesh)

- Welding power supply: AC or MFDC

-

Single-station fan guard welding machine

Single-station fan guard welding machineThis equipment is designed for the production of industrial fan guards, offering automated wire winding and welding. The automation features contribute to enhanced welding efficiency and improved welding quality, ensuring a more streamlined and precise manufacturing process for industrial fan guards.

- Wire diameter: 2-8mm

- Diameter: 200-800mm (customizable)

- Automatic winding unit: optional

- Dual-station mechanism: one side for winding wire, the other side for welding, doubling the efficiency.

- Welding power supply: AC or MFDC

-

Welded wire mesh trimmer

Welded wire mesh trimmerThis equipment is specifically designed for trimming the edges of the welded mesh, ensuring a smooth and scratch-free finish.

- Wire diameter: 2-6mm

If you have any business inquiries or product questions, please feel free to contact us.