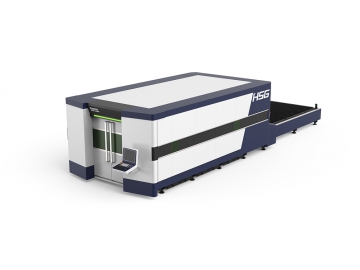

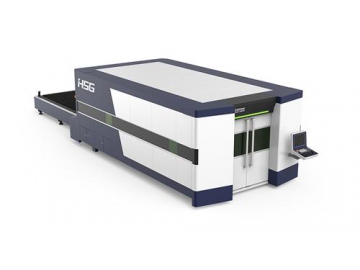

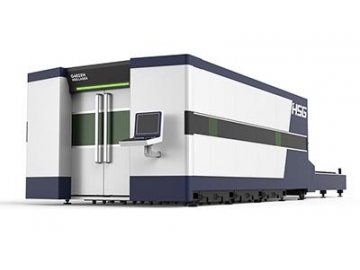

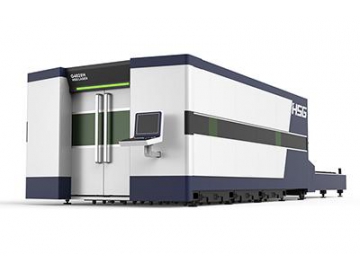

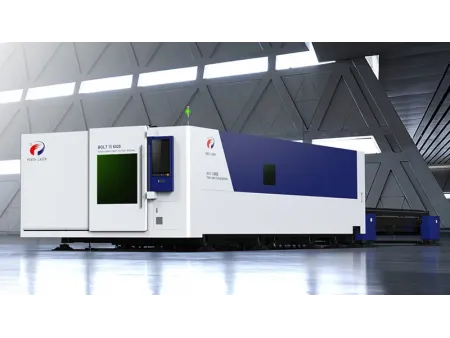

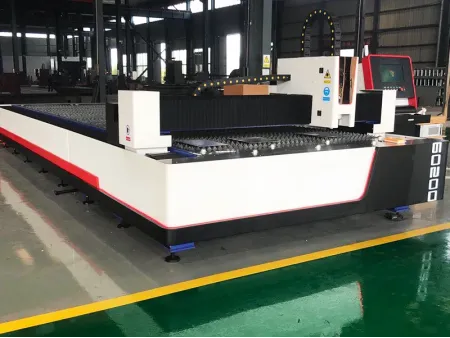

G4020H Fiber Laser Cutting Machine

As the second generation product, the G4020H fiber laser cutting machine features graphite anti-burning technology to avoid damaging to the machine tool caused by high temperatures during the metal processes of the high powered fiber laser cutter. This ensures a safer operation and increases the machine durability.

Compared to other models, the G4020H laser cutter is equipped with IPG fiber lasers with power levels that can reach up to 15kw. It features a cutting quality and surface that is outstanding, with a smooth, burr free surface. It can process stainless steel at 40mm thick and aluminum up to 50mm thick.

Applicable materials: stainless steel, carbon steel, aluminum, brass, copper, galvanized plate and cold-rolled sheet, and more.

Application industry: The G4020H laser cutter is widely used for external processing of metal sheets, home decoration (window grilles, laser cut screen door), elevators, aerospace components,instruments and more.

| Processing Area | 4000mm×2000mm |

| Laser Power | 4000W-15000W |

| Max Moving Speed | 150m/min |

| Max Ac Speed | 1.5G |

| Positioning Accuracy | 0.05mm/m |

| Reposition Accuracy | ±0.05mm |

| Power Supply | 380V/50Hz |

| Whole machine weight | 18000kg |

| Machine Dimensions | 11500mm×3500mm×2500mm |

* Customizable size: 3m × 1.5m, 6m × 2m, 8m × 2m.

** We offer lasers in a variety of powers. The material thickness to be cut is directly dependent on the laser power.

- Stainless steel

- Carbon steel

- Brass

- Copper

- Aluminum

- Galvanized steel

- Cold rolled steel

- Titanium

- Electrolytic steel

- Silicon steel

- Laser systemIPG High power fiber laser system features powerful cutting ability.

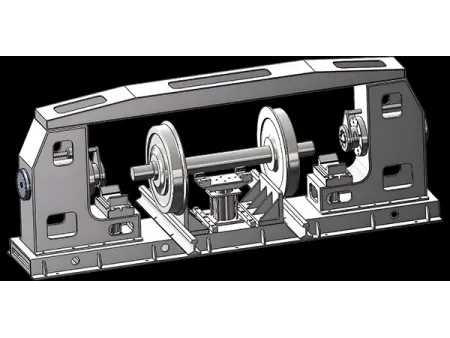

- High rigidity bedThe G4020H laser cutter is most often installed in high power models, so that the installation of a stable, rigid bed is necessary. In this particular model, a honeycomb bed is used, with the honeycomb cell structure made from carbons structural steel that has been welded as a dislocation structure, then the bed goes through an annealing process and vibration aging treatment in order to relieve processing stress. Thanks to the advanced technology, we can guarantee that the bed will operate normally for at least 20 years with no deformation.

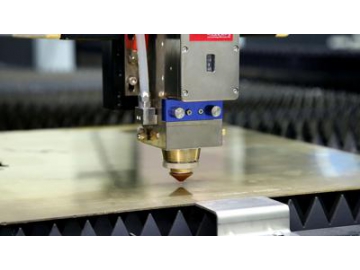

- Cutting headThe G4020H Fiber Laser Cutting Machine can be equipped with the laser head from German Precitec. This laser head can automatically focus in order to increase the cutting speed and ensure a smooth cutting surface.

- Servo motorThe electric and drive systems provided by Japan Sanyo Denki offer customers a faster rotation speed and better stability.

- Rack and pinion systemHSG LASER uses a rack and pinion reducer from ALPHA. Not only will it not become stuck and stop, but it can also match perfectly to various machines.

- CNC systemHSG LASER uses a CNC system from Beckhoff along with nesting software from SIGMANEST, both of which save raw materials and increase the processing efficiency.