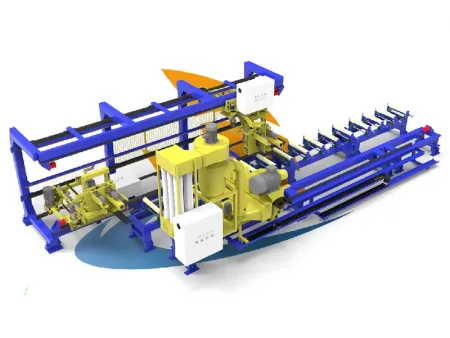

Extrusion Press machine

Horizontal Extrusion Machine

Description

Impact cold extrusion press machine is also called horizontal punching machine which is mainly used for the one-time extrusion of aluminum can products which have large diameter. This LJC aluminum aerosol can extruder can make the aluminum slugs into cylindrical shapes of other shapes. It can be set up with different extrusion process.

The slat chain lift conveyor sorts out the aluminum slugs and sends them into the blanking guide rail. Then the manipulator for transferring sheet stock will send the slugs into the punch cavity accurately. Under the effect of crankshaft connecting rods and sliders, the gap between the head and the die block can control the thickness of the tubular products. And the ringed gap between the punch and bottom die can mold the slugs by cold extrusion in one time, form the cylindrical shapes and strip automatically. Finally, the conveyor chain will output the cylindrical shapes in order. This machine can be used independently and can also be connected with other equipment to form an automatic production line.

Technical Parameters| Applicable can diameter | φ35-φ59mm |

| Applicable can length | 80-250mm |

| Maximum production speed | 120/min |

| Main motor power/total power | 37KW/37.28KW |

| Minimum intake pressure | 0.4MPa |

| Slider stroke | 350mm |

| Net weight | 1100KG |

| Dimensions | 3195*1558*1585mm |

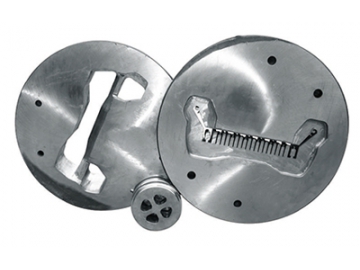

- The impact cold extrusion press machine adopts integral cast steel structure and one-time casting. It has high rigidity and strong impact resistance. Its bed frame is processed by large machining center and the crankshaft and other parts of it are processed by CNC equipment. So this machine has high precision.

- This horizontal punching machine adopts electrical chain operation and fully enclosed structure. It has stable performance and low noise. It also has a protective function which enables it to stop automatically when the output of the cans doesn't go well.

- The whole machine adopts PLC control which is both sensitive and reliable. There are dedicated motors for the control of the can length so that the adjustment of the can length is fast and convenient. And it uses speed control by frequency variation.

- The fixed seat of the head adopts double bevel adjustment form which can locate accurately. The seat and the connecting rod adopt adjustable structures to eliminate the small gap caused by the abrasions which appear because of the equipment's long term operation so that it will guarantee the equipment to operate with high precision for a long time.

- All the key parts are made from high quality copper which can reduces the friction coefficient, increases wear resistance and extends the service life.

- The fully enclosed overall design puts an end to the pollution of the working ground caused by the leak of the lubricating oil.

Electric box

Electric box  The rove iron of the crank

The rove iron of the crank  Robot discharge

Robot discharge