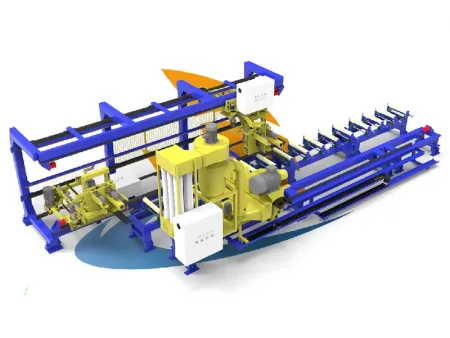

Extrusion Press machine

Tube punch machine, Horizontal Extrusion Machine

The introduction of product

The impact extrusion press machine is also called horizontal punching machine, which is a special production device for extruding aluminum slugs into tubes, or barrel with other shapes. This machine can set different extrusion process to extrude aluminum pipes with different sizes.

The LJG02 aluminum impact extrusion press for aluminum tubes is a new generation of high-speed aluminum impact extrusion machine, which developed and designed by our company. The equipment is automatically arranged by a vibrating feede to arrange the aluminum slugs and regularly feed it into the baiting guide rail, and the feeding manipulator accurately feeds the slugs into the stamping cavity. Under the action of crank train and slider, the gap between punching and module hole controls the thickness of pipe. Extruding the slugs into shape through the annular gap between the die block and the punching. Forming blank tube and stripping automatically. The output of tubes is orderly through the conveyor chain.

Technical Parameters| Nominal pressure | 800kN |

| Suitable diameter | φ13.5-φ27mm |

| Maximum applicable length | 175mm |

| Production rate | 90-120 tubes /Minute |

| Total power | 8.07KW |

| Intake air pressures | 0.6Mpa |

| Weight | 5200kg |

| Dimension | 2730*1315*1550mm |

- The full machine is controlled by PLC, which has high degree of automation, stable and reliable performance.

- This machine uses whole forging steel structure, casting at one time, which has good rigidity and impact resistance. The lathe bed is finished by large machining center, crank and other parts are also processed by compute numerical control equipment. The equipment has high accuracy.

- The machine is processed by interlocking with totally enclosed structure. It has stable performance, low noise and the function of automatic stop protection for bad pipe.

- The punch holder uses the form of double bevel adjustment to make the location accurate. The punch holder and connecting rod uses adjustable structure, which can eliminate the gap caused by the long-term wear of the equipment and ensure the long-term high-precision operation of the equipment.

- All of the key parts use high quality copper, which reduces friction coefficient, increases wear resistance and extends service life.

- The fully enclosed integral design for bed lathe eliminates the pollution to the working ground because of the oil leakage.

Transmission chain

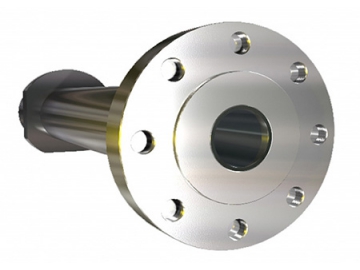

Transmission chain  Extrusion punch

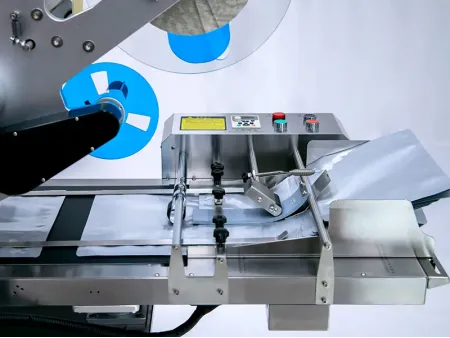

Extrusion punch  Control panel

Control panel  Distribution box

Distribution box  Drive device

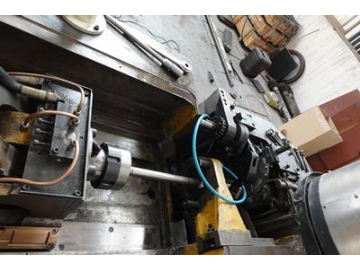

Drive device  Crank extrusion link

Crank extrusion link  Feeding tube

Feeding tube  Cam

Cam