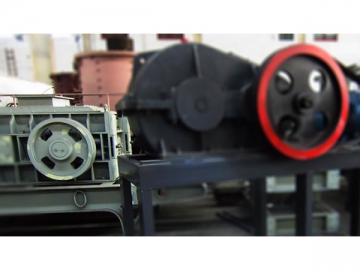

Hydraulic Roller Crusher

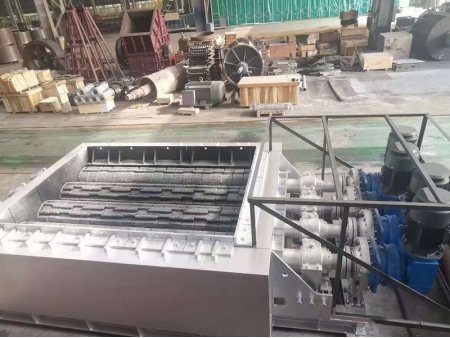

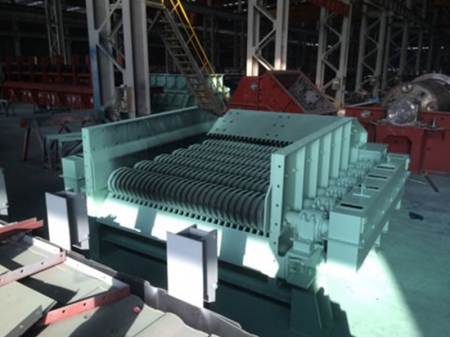

Hydraulic roller crusher is composed of fixed roller and movable roller. Material is fed on the top of the rollers, and extruded by the high pressure of 50-100MPa, then discharged at the bottom of the machine. There are large numbers of cracks inside the semi-finished particles, that can reduce the energy consumption greatly during crushing.

Principal

These roll crushers use surface friction to squeeze and crush materials that enter the mouth of the crushing machine. When it is used for coarse crushing, it needs to increase the crushing ratio which can be performed by using rollers with teeth or groves on the surface.

Feature

1. Used for the crushing of special solid materials. Adjustments to the heavy machinery can be made depending on the hardness of the material.

2. A mobile roller is used to avoid belt slippage.

3. The maintenance of the entire machine can be completed for less than 2000 RMB.

4. Crushing efficiency is greatly improved by separating materials that are too large to be crushed.

5. Power consumption is half that of traditional hammer crushers.

6. When the material is too hard to be crushed, the roller is spring loaded to give in order to prevent damage to the machine.

| Model | Roller dia. (mm) | Roller width (mm) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Feed opening size(mm) | Motor power (kw) | Overall dimension (mm) | Weight (kg) |

| 800 | 600 | <30 | 0.5-10 | 15-45 | 600×500 | 18.5×2 | 3490×2884×1035 | 8600 | |

| 1100 | 800 | <50 | 0.5-10 | 45-100 | 800×700 | 45×2 | 4398×3354×1200 | 17600 | |

| 1400 | 1000 | <60 | 0.5-10 | 100-200 | 1000×900 | 90×2 | 5800×3850×2100 | 36000 | |

| 400 | 252 | < 30 | 3~8 | 3~5 | 100×200 | 5.5×2 | 1850×1100×800 | 1300 | |

| 600 | 400 | < 40 | 3~8 | 5~20 | 370×400 | 11×2 | 2555×2490×1050 | 4300 | |

| 800 | 600 | < 60 | 3~10 | 15-40 | 600×500 | 22×2 | 3490×2884×1035 | 8500 | |

| 1000 | 700 | < 80 | 3~12 | 20-50 | 700×600 | 30×2 | 4398×3354×1190 | 12000 | |

| 1200 | 750 | < 90 | 3~14 | 30-80 | 800×600 | 45×2 | 4547×3653×1478 | 17000 | |

| 1500 | 800 | < 100 | 3~15 | 40-100 | 800×800 | 75×2 | 4832×4037×1765 | 27000 | |

| 1800 | 800 | < 130 | 3~18 | 60-130 | 800×800 | 90×2 | 5645×3850×2092 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.