Stainless Steel Elbow Pipe Fittings (45° Elbow, 90° Elbow, 180° Elbow)

- Stainless steel mitered elbow

- Large size welding elbow

Stainless steel elbow pipe fittings are widely applied in industries of petroleum, natural gas and electric power for connecting two lengths of pipe to redirect the fluid flow direction in pipe systems. Our company is able to provide a whole range of stainless steel elbows, which consists of standard elbows including 45°, 90°and 180°elbow as well as customized elbows with any angle. Therefore, customers’ various requirements for direction change could be fully satisfied.

Common stainless steel features great resistance to corrosion, high temperature and acid, which further ensures that our stainless steel elbow is suitable for conveying varieties of corrosive fluid and could work smoothly in circumstance with high temperature and high pressure.

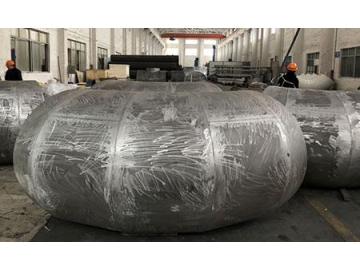

Sample Exhibition 1. Large size stainless steel elbowFor production of large size stainless steel elbow, two steel plates are placed into corresponding mould for compression molding first via hydraulic press. Then butt welding will be done to attach these two steel pieces together. Through this process, the maximum caliber of the seamed stainless steel elbow we could produce is 100 inches. Furthermore, we are also capable of manufacturing miter elbow with the largest caliber up to 160 inches by welding multiple steel plate formed pieces together if customers need.

- 96 inches caliber elbow

- 104 inches caliber elbow

- 1.5m caliber mitered elbow

- 304L stainless steel elbow

- 42mm wall thickness elbow

- 50mm wall thickness elbow

- Butt welding elbow made by steel plate

- Elbow formed by steel plate

In our company, there are cold press forming machines exclusive for production of seamless elbow made of stainless steel. In addition, we can also produce large size seamless elbow by hot press forming by mandrel process for customers.

- Cold press forming elbow

- Raw Cutting SS Pipes

- Cold Forming SS Elbows

- Semi-finished SS Elbows

Through forging process, we are also able to manufacture stainless steel socket weld elbow or threaded elbow.

- Forged SS Elbows

An extensive use of stainless steel fittings can be found in the following industries:

- Petrochemical industry: Oil refining, ethylene, coal to oil, coal to olefins and other projects.

- Natural gas industry: LNG ships, LNG terminals, and natural gas pipeline projects.

- Power station industry: In thermal power plant, the water pipeline (usually stainless steel) used for supercritical units, circulating fluidized beds, power generation boilers, steam turbines, generators and other equipment, including reheater tube, superheater tube, water screen tube, economizer tube, downcomer and header, etc.

- Machinery and equipment manufacturing industry: Equipment structures such as pressure vessel, heat exchanger, fluid control, hydraulic transmission, instrumentation and others.

- Others: Shipbuilding, papermaking, desalination, food production and other industries; Aviation, aerospace, military, nuclear power plants and other projects.

| Parameters | DN15-DN2500 (1/2"-100") |

| Bending radius (R) | 1D, 1.5D, 2D, 3D, etc |

| Wall thickness | Conventional wall thickness range: Sch 5s to Sch XXS Maximum wall thickness: 100mm |

| Standard | ASME B16.9, MSS-SP-75, AWWA C208, DIN2605, DIN EN10253, JIS B2312, JIS B2313, GB/T13401, GB/T12459, GB/T27684, SH3408, SH3409, GOST17375, DL/T515, SY/T5257, etc. |

- ASTM SA/A403 GR.WP304, WP304H, WP304L

- ASTM SA/A403 GR.WP316, WP316H, WP316L

- ASTM SA/A403 GR.WP317, WP317H, WP317L

- ASTM SA/A403 GR.WP321,WP321H

- ASTM SA/A403 GR.WP347, WP347H

- ASTM SA/A403 GR.WP310S, WP310L

- ASTM SA/A403 GR.WP904, WP904L