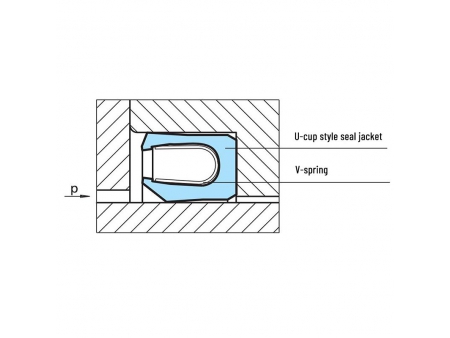

Cantilever Spring Energized Seal

Request a Quote

U-cup style seal jacket

V-spring

V-spring

FJSEALS cantilever spring energized seal is a single-acting seal, and makes use of a V shaped corrosion resistant ring embedded in a U-cup seal jacket. With a linear load curve and excellent deflection range, cantilever spring seals are a very versatile product, providing good sealing performance, low friction and long service life. Cantilever spring seals are best suited for reciprocating applications such as shocks, hydraulic cylinders, pumps and compressors.

Technical parameter

| Max. dynamic load | 45Mpa |

| Max. static load | 60Mpa |

| Reciprocating motion | 15m/s |

| Rotary motion | 1m/s |

| Operating temperature | -70℃ to 260℃ |

| Media | Virtually all fluids, chemicals and gases |

Note: The pressure and speed should lower at high temperature conditions.

Benefits

- Ideal for reciprocating or rotating applications

- Low fabrication

- Good abrasion resistance and dimensional stability

- Universally liquids, gas and chemicals compatibility

- Withstands rapid changes in temperature

- Safe for contact with food and medicine

- Outstanding resistance to aging

- Capable of disinfection

- Suitable for high cleanliness product

- Interchangeable with the O-rings and back-up rings combination

Standard materials

- Seal jacket: Polymer FJ-0234

- Spring: S (stainless steel)

Options of cantilever spring energized seal

- RS19 for rod seal

- PS19 for piston seal

Note: Please

Application

- High temperature sealing

- Corrosion resistant seal

- Hydraulic component seal, such as energized seals for water pump

- Pneumatic seals

Industries served

- Corrosion resistant spring-energized seal for chemical processing

- Industrial equipment

- Pharmaceutical industry

- Food & beverage

- Aerospace & aircraft

Firstly, they provide a higher level of leak protection compared to traditional O-rings. The springs resist the pressure they are subjected to. The seals are typically exposed to pressurized media environments.

V-spring seals provide good friction and leak control under moderate pressure and temperature conditions. They are best suited for applications that require resistance to aggressive chemicals, acidic environments, and rapid gas decompression (RGD).

Among all available spring types, V-shaped springs have the widest deflection range. They are particularly suitable for very large diameter components where hardware misalignment, dimensional tolerances, and clearances are substantial. The increased deflection range ensures that the seal is always in contact, even in fluctuating gland conditions.

Our spring-energized PEEK seals, spring-energized stainless steel seals, and other industrial seal products can be used as high-pressure seals.

We have adopted world-class high-precision sealing processing equipment, pure imported raw materials and strict quality management systems to rapidly produce precision sealing products of any shape, size, and material to meet customer needs.