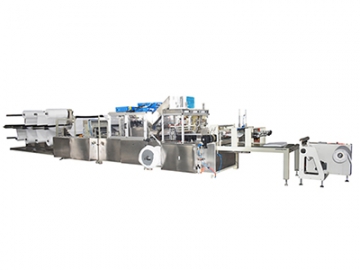

Fully Automatic Non-woven Bag Making Machine, WFB-KT

Plastic Bag Machine/ Non-Woven Bag Maker/ Bag Maker

Main Introductions

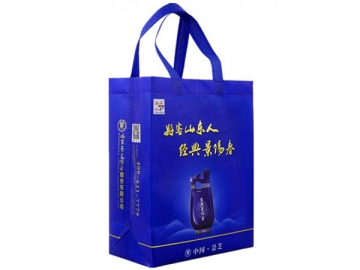

This machine is our newest fully-automatic non-woven bag making machine. It uses environmentally-friendly non-woven fabrics as a raw material. The equipment features optical electrical and ultrasonic bonding technology to quickly and efficiently produce all of your packaging. The finished bags compared to common bags are more aesthetically pleasing and much stronger. They are widely used in clothing, footwear, and gift packaging bag production.

Applied Materials

This machine is suitable for PP non-woven fabric, regeneration non-woven fabric and lamination non-woven fabric material.

Material thickness range: 20-120gsm.

What is the difference compared to other bag making machines?

1. The technology allows for the production of an entirely new type of bag that is more efficient to produce and environmentally friendly.

2. In general cases, non woven box bag made by machine need to be turned around. This machine skips that process. It is finished in one process with an automatic folding component.

Product Purpose

1. To protect the environment.

2. Reduce labor costs, higher precision, less waste and faster operation.

-

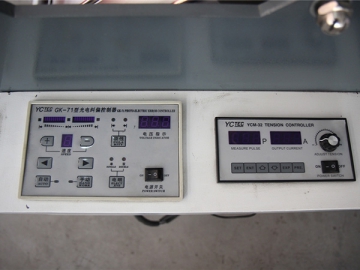

Control panel

Control panel -

Delivery

Delivery -

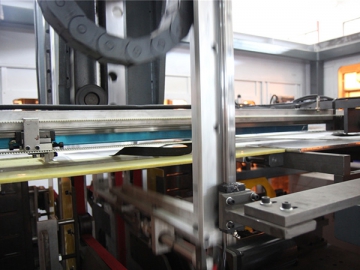

EPC

EPC

-

Finalize the design

Finalize the design -

Handle sealing

Handle sealing -

Material

Material

| Model | WFB-KT |

| Size of Bag(L*W*H) | 250*100*200mm--400*160*400mm |

| Material Thickness | 80-130g |

| Max.Length of Handle loop | 60mm |

| Production Speed | 20-60pcs/min |

| Voltage | 220v/380v |

| Total Power | 28kw |

| Machine Weight | 6.0t |

| Overall Demensions(L*W*H) | 8000*2400*3000mm |

Speed Comparison

Our speed is 60pcs/min.

Other's speed is 50 pcs/min.

Machine Produce Process

Raw material steel -- cut and weld -- paint -- assemble configuration -- connect wiring -- finish -- test

Main Configuration

1) Servo Motor: Japan Yaskawa

2) PLC: Japan Mitsubishi

3) Stepping Motor: SOYO stepping motor

4) Transducer/Sensor: Germany Omron

5) Computer control adjustable-speed

6) Air Cylinder: Taiwan AirTAC air cylinder

7) Ultrasonic: Taiwan special ultrasonic

8) Bearing: Japan NSK bearing

9) Touch screen: Taiwan Weinview

10) Thermometer

11) Electric Switch

12) Computer control system

13) Automatic tracking whole process

14) Use a dial indicator to locate the mold

15) Automatic load

16) Automatic tension

17) Handle loop corrector

18) Automatic neaten bags

FAQ:

Q: How many people operate the machine?

A: One or two persons required.

Q: How many years of warranty?

A: All of our products have a one year warranty. We have a professional after sales service team. When machine parts are damaged, we will exchange them for free within the one year warranty.

Q: Do you supply install and train in my country?

A: Yes, we will arrange travel for our engineers to the buyer’s factory for machine installation and training. The buyer should pay the round-trip ticket cost, hotel, and food for our team. Usually this can be completed within a week. The buyer is also responsible for paying 80 USD/day salary to our engineer.

Q: If there is some problem with machine running, how long can you solve it?

A: We will reply to you within 24 hours and solve it within 48 hours.