Fully Automatic T-Shirt Bag Making Machine (200pcs/min×2)

Request a Quote

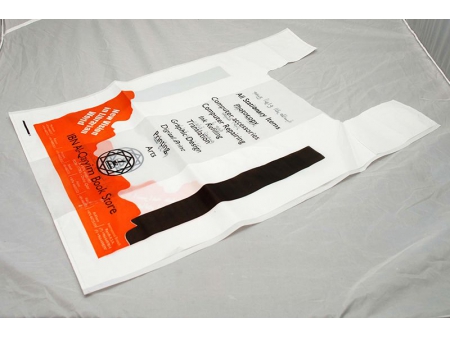

Suitable for making printed / unprinted shopping bags made of HDPE

Video

This fully automatic T-shirt bag making machine is great for producing both printed and unprinted vest bags made from HDPE or LDPE film rolls. These plastic bags are ideal for supermarkets and other retail environments.

TPLAST’s automatic bag making machine is powered by PLC control, boasts two servo motors for consistent length, and a touch screen display to accomplish feeding, sealing, cutting, punching holes and transporting all in one go. It is incredibly efficient, highly automated and promises great economic returns.

Technical Parameters

| Model | RGHQ-500X2B | RGHQ-400X2B |

| Max. sealing and cutting width (mm) | 480*2 | 380*2 |

| Max. sealing and cutting length (mm) | 650 | 650 |

| Product thickness (mm) | 0.015-0.035 | 0.015-0.035 |

| Bag making speed (pcs/min) | 200*2 | 200*2 |

| Air pressure (kg/cm2) | 5 | 5 |

| Power (kW) | 7 | 9 |

| Weight (kg) | 2500 | 2000 |

| Dimension (m) | 6*1.4*1.6 | 6*1.4*1.6 |

Application

This fully automatic T-shirt bag making machine is suitable for making printed and unprinted plastic shopping bags for supermarkets, shopping malls, retail stores, convenience stores, and more.

Details

- Unwinder 1. Air cylinder is utilized to automatically load the film rolls

2. Frequency motor is used for the control of unwinding, Taiwan Eura inverter is equipped - Sealing and Cutting Units 1. Panasonic photocell detects the print mark, making the bag printing reliable

2. High quality statics box from Taiwan

3. Using Taiwan advanced air blowing feeding technology for bag feeding

4. Stronger cutting knife holding shaft

5. Sealing knife is made of high quality copper

6. Cutting knife adopts Taiwan design - Punching Unit 1. PU material is utilized as the best for the conveyor to ensure a longer life span

2. High-quality cutting knife from Japan

3. 15mm thick nylon plate provides strong support for bag making

4. PLC control with touch screen, simplifying the operation of hole punching

5. Suitable for making both folding bag and non-folding bag - Machine Structure 1. The machine structure is constructed using 12mm thick steel plates, providing outstanding stability when the machine is in operation

2. The machine body is coated with car paint

3. High level of automation helps save labor intensity - Control Panel 1. PLC control coupled with touch screen provides ease of use, and English manual is available

2. Taiwan Yudian temperature controller

3. Electric components are from Chint, a reliable renowned supplier in China