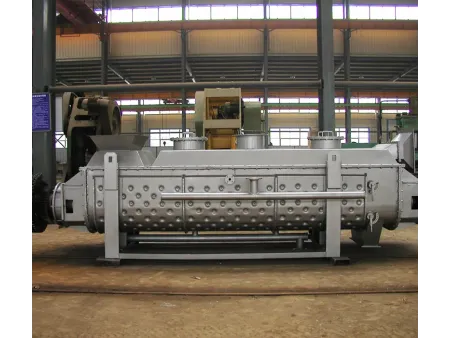

Paddle Dryer

Industrial Drying Equipment

- Heat transfer area 1-300m²

- Motor power 1.5-220kW

The paddle dryer is a horizontal, indirect heating dryer with integrated agitation, designed for drying, heating, cooling, crystallization, and thermal reactions of pastes, sludges, powders, and granules. It operates on the principle of heat conduction and is engineered for efficient thermal processing of materials with varying consistency.

The core structure features a W-shaped shell with jacket housing one or more pairs of hollow, low-speed rotating shafts with welded paddle blades. Heat transfer media such as steam, thermal oil, or hot fluid is circulated through both the jacket and the hollow paddles. This dual-zone design allows for different temperature zones within the same machine, significantly improving heat transfer efficiency compared to standard conductive dryers. Paddle dryers are available in atmospheric, sealed, and vacuum configurations, making them suitable for a wide range of thermal processes, including drying, heating, calcination, sublimation, pyrolysis, and chemical reactions. For applications involving volatile organic compounds or hazardous substances, its airtight construction ensures safe operation. For heat-sensitive materials, vacuum drying at low temperatures can be applied to preserve product stability.

- Energy efficient

The paddle dryer consumes 30% to 60% less energy compared to conventional convective drying systems, thanks to its highly efficient heat conduction design. - Closed system operation

The entire process is carried out in a sealed environment, preventing contamination and eliminating emissions, making it ideal for sensitive or hazardous materials.

Paddle dryers are widely used for drying powders and granules in the petrochemical, environmental, and feed production industries. Its versatility and sealed operation make it suitable for processing materials with strict safety or cleanliness requirements.

| Model | Heat transfer area (m²) | Motor power (kW) | Rotation speed of shaft (r/min) | Dimensions (mm) | ||

| Length | Width | Height | ||||

| 1 | 1.5~3 | 1.5~15 | 1500 | 600 | 740 | |

| 2 | 2.2~4 | 1.5~15 | 2340 | 600 | 740 | |

| 2.5 | 3~5.5 | 1.5~15 | 2500 | 600 | 800 | |

| 4 | 3~5.5 | 1.5~15 | 3300 | 800 | 800 | |

| 6 | 4~7.5 | 1.5~15 | 3480 | 1380 | 923 | |

| 8 | 5.5~11 | 1.5~15 | 3980 | 1380 | 923 | |

| 10 | 7.5~11 | 1.5~15 | 4480 | 1380 | 923 | |

| 15 | 11~15 | 1.5~15 | 5970 | 1422 | 1354 | |

| 20 | 11~15 | 0.5~10 | 6670 | 1422 | 1354 | |

| 25 | 15~22 | 0.5~10 | 7370 | 1422 | 1354 | |

| 30 | 15~30 | 0.5~10 | 6084 | 2614 | 1738 | |

| 40 | 22~37 | 0.5~10 | 6781 | 3230 | 1853 | |

| 60 | 37~55 | 0.5~10 | 7426 | 4190 | 2570 | |

| 70 | 37~75 | 0.5~10 | 8136 | 4190 | 2570 | |

| 80 | 37~75 | 0.5~10 | 8941 | 4385 | 2570 | |

| 100 | 55~75 | 0.5~10 | 9660 | 5196 | 2760 | |

| 120 | 75~110 | 0.5~10 | 10900 | 5196 | 2760 | |

| 160 | 75~150 | 0.5~10 | 9000 | 4500 | 2500 | |

| 200 | 110~150 | 0.5~10 | 9300 | 5500 | 2700 | |

| 240 | 132~220 | 0.5~10 | 9300 | 5850 | 2700 | |

| 300 | 160~220 | 0.5~10 | 9300 | 8000 | 2700 | |

| Note | Double shaft:lower than 120m² Four shaft:greater than 120m² | |||||