Spin Flash Dryer

Industrial Drying Equipment

- Dimensions 6500×4200×7530mm

- Power 1.1-55kW

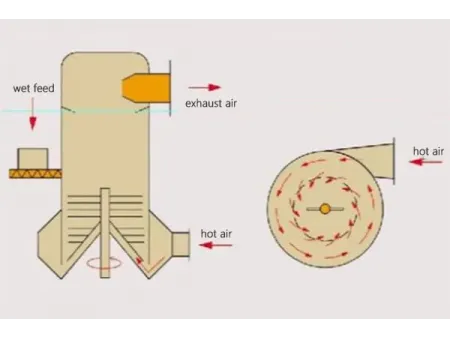

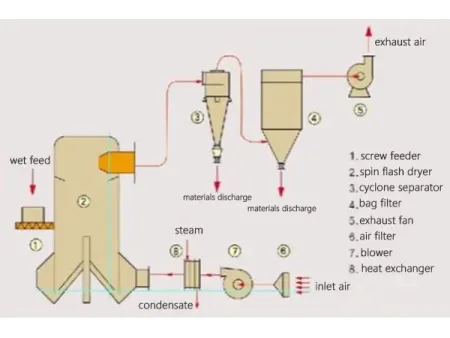

The spin flash dryer is a vertical drying system equipped with a built-in rotating disperser, combining the functions of fluidized bed drying and airflow drying in a single unit. It is designed for the continuous drying of filter cakes, pastes, and slurry-like materials. This drying equipment not only dries but also pulverizes and classifies materials during the drying process, making it ideal for materials with high moisture content and poor flowability. The integrated design enables efficient thermal processing in a compact footprint, making it suitable for demanding applications across chemical, pharmaceutical, and materials industries.

Clean hot air, heated by an external source, enters the drying chamber tangentially, forming a strong vortex flow in combination with the internal mechanical disperser.

Wet material is fed into the chamber in controlled amounts. Under the combined action of the vortex airflow and mechanical agitation, the material is rapidly dispersed, fragmented, and dried.

A classifier located at the top of the chamber separates particles based on size. Fine, dried powder that meets the target moisture and particle size is carried out through the top outlet and collected by downstream separation equipment. Larger or partially dried particles are blocked by the classifier ring and recirculated within the chamber for further drying and pulverization. The clean exhaust air is safely discharged through an induced draft fan.

- Stabilized drying flow

The rotor at the conical base of the drying chamber promotes uniform fluidization of product particles and ensures smooth, stable operation of the internal agitator. - Anti-adhesion design

Scraper blades mounted on the agitator help redirect material that adheres to the chamber wall back into the drying zone, preventing overheating and buildup. - Versatile material handling

Capable of processing both non-sticky and sticky filter cakes, as well as thick pastes. Drying and pulverizing are completed in a single step, enhancing efficiency and reducing energy consumption. - Controlled residence time

Rapid processing with minimal heat exposure makes it suitable for heat-sensitive materials. - Integrated product control

A built-in classifier at the discharge outlet ensures that only materials meeting moisture and particle size specifications are discharged as finished product.

Our spin flash dryers are ideal for drying powdered, caked, paste-like, and slurry materials. It is widely used in the chemical industry for products such as H-acid, acid dyes, insecticides, and other moisture-rich materials requiring rapid and efficient drying.

| Model | Dimensions (mm) | Power (kW) |

| 2000×600×2500 | 1.1~3 | |

| 2700×800×3500 | 3~5.5 | |

| 2800×800×3600 | 4~11 | |

| 3280×1350×3700 | 5.5~11 | |

| 3400×1500×3800 | 7.5~15 | |

| 4320×1900×3960 | 7.5~15 | |

| 4772×2388×4918 | 11~22 | |

| 5200×2780×5250 | 15~30 | |

| 5500×3170×5590 | 18.5~45 | |

| 5900×3600×6500 | 22~45 | |

| 6500×4200×7530 | 30~55 |