Automatic Side Seal Loop Handle Bag Making Machine

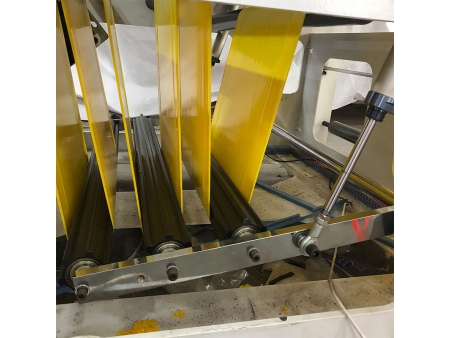

This fully automatic side seal loop handle bag making machine is among the finest options available on the market. Equipped with an advanced Weinview touch screen operation system from Taiwan, this loop handle bag making machine has several efficient features such as photoelectric sensor web guide control, automatic tension control of magnetic powder and automatic counting, earning it a reputation as a premier plastic bag manufacturing machine. And, with automatic web guiding, triangle folding, bottom gusseting, top folding, heat sealing, soft loop handle welding, poly strings and side sealing, it discharges finished products directly. Furthermore, it can automatically stop when running out of film and features electric-eye tracking, allowing it to operate at a high level of efficiency.

| Model | RG-ZD800 |

| Product length (height) | 250-700 mm |

| Product width | 250-600 mm |

| Bag making speed (soft loop handle bag) | 60-120 pcs/min |

| Bag making speed (poly string bag) | 60-85 pcs/min |

| Top folded | 50 - 75 mm |

| Bottom inserted | 30-70 mm |

| Handle length | 360 mm |

| Handle width | 30 mm |

| Max. feeding width | 1600 |

| Air pressure | 6 Hp |

| Total power | 7.5 kW (Max. 15kW) |

| Weight | 5000 kg |

| Dimension | 11000*2500*2050 mm |

- By adopting an automatic tension control system for feeding, the tension of the raw material can be automatically adjusted.

- The bag making machine features pneumatic loading, air pressure is adjustable

- Pneumatic traction rollers enable feeding more smoothly

- No stretch servo guarantees a smooth and strong seal

- All servo driven, providing a smooth operation

- Automatic counting system, such as bag making counter or loop handle counter, can be used to quickly and accurately count different types of items

- The conveyor belt speed is regulated through frequency conversion, ensuring orderly and smooth discharging

- Water cooling device is located near the sealing unit, allowing the material to become more even and solid

- Touch screen (Taiwan Weinview)

- Electronic valve (Taiwan)

- Stepper motor (Suchuan, Shanghai)

- Cylinder (Taiwan AirTAC)

- Ultrasonic electric eye (Julong)

- Photoelectric sensor (Italy Datalogic)

- Servo motor (Delta)

- Switching power supply (Schneider)

- Synchronous motor (customized in China)

- Reduction motor (LiBang, Zhejiang)

- Frequency converter (Delta)

- PLC (Inovance)

- Asynchronous motor (LiChao, ShangHai)