Automatic BFS Ampoule Inspection Machine

Request a Quote

Highlights

- Supports appearance and foreign object inspection for 1–20ml BFS plastic ampoule strips

- Inspection speed up to 120 strips per minute

- 360° full-coverage inspection with optional straight-line or rotary infeed modes

- Fully self-developed structure and technology with independent intellectual property rights

- Designed in compliance with FDA and EU regulations

- Core components sourced from top international brands such as Basler (Germany) and Mitsubishi

Automatic Visual Inspection (AVI)

Pharma visual inspection equipment for detecting various defects of blow-fill-seal (BFS) plastic ampoules ranging from 1ml to 20ml at speeds up to 120 strips/min

Technical Specifications

- Speed: ≤120strips/min (5pcs per strip)

- Applicable container: ≤20ml BFS plastic ampoules (blow-fill-seal ampoule strips)

- Standard inspections: Visible foreign objects, text, deformation, liquid level, scale lines, black dots, etc.

- Number of inspection stations: 15 stations (14 sets of cameras in total)

- Channels: 1 channel for defective products, 1 channel for qualified products (more channels can be added based on customer needs)

- Power: 3.5kW

- Noise level: ≤75dB(A)

- Power supply: Three-phase five-wire, 380V AC, 50Hz

- Machine dimensions (L×W×H): 4060×1780×2150mm

- Machine weight: 2500kg

Features

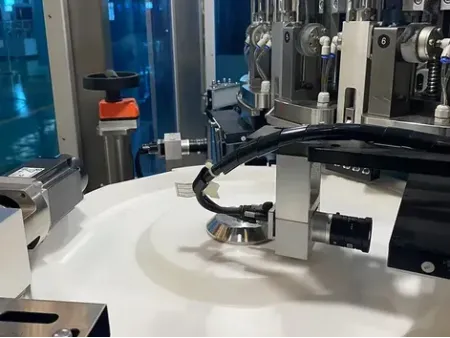

- Uses a rotary clamping mechanism to securely hold ampoule strips in place, ensuring consistent positioning and significantly reducing false rejections caused by product irregularities.

- Inspects both sides (A/B) of the clamped area before entry and after discharge. Once clamped, the strips are suspended for 360° inspection without blind spots, minimizing interference from the track and improving accuracy.

- Combines traditional and AI-driven image processing algorithms to detect both defined and unpredictable defects. The system supports deep learning for continuous upgrades, ensuring reliable long-term performance.

Working Principle

The automatic BFS ampoule inspection machine uses camera-based visual inspection technology to identify product defects. Multiple inspection stations are equipped with various combinations of stroboscopic light sources that capture images from multiple angles. These images are analyzed by intelligent algorithms at dedicated processing units. Based on the results, the PLC system controls the machine to direct products into the appropriate channels for qualified and unqualified items.