Fluoropolymer Coating

Request a Quote

Fluoropolymer Spray Coating Services

High-purity fluoropolymer coatings for –190°C to 260°C environments, using DuPont, Daikin, and Solvay materials for industrial applications and semiconductor manufacturing.

Fluoropolymer Coating for Industrial Applications

Fluoropolymer Coating for Semiconductor Manufacturing

Fluoropolymer Spray Coating Processes Available

- Fluoropolymer Coating for Industrial Applications

PFA coating, PTFE (F4) coating, FEP (F46) coating, ETFE (F40) coating, ECTFE (F30, Halar) coating, PVDF coating - Fluoropolymer Coating for Semiconductor Manufacturing

PFA high purity coating, ECTFE (F30, Halar) high purity coating, PVDF coating, PFA high purity anti-static coating, high purity of 0.5-1 ppb

What Makes Us Unique

At ChiNaite, every detail in our coating process is designed to ensure quality, consistency, and compatibility with demanding applications.

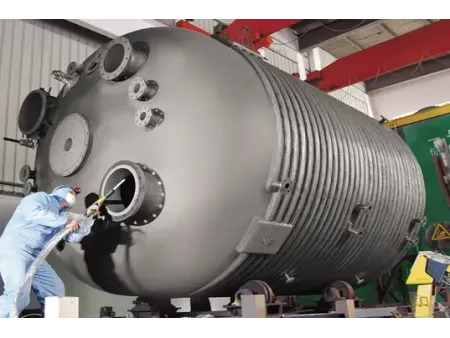

- Precision-Controlled Curing

We use hot air circulation ovens imported from Japan to ensure uniform temperature control during curing. With a maximum capacity of 5 meters in diameter and 10 meters in length, our largest oven is one of the biggest used for fluoropolymer coating in China. To handle a variety of equipment sizes, we operate a total of 25 ovens in different specifications. - Certified Raw Materials

All coating materials are imported and approved by Chemours (DuPont, USA), Daikin (Japan), and Solvay (USA), ensuring consistent performance and material traceability. - Dedicated Sandblasting Areas

To prevent cross-contamination, stainless steel and carbon steel vessels are handled in separate sandblasting rooms, three for each material type, enabling strict quality control at every stage. - Electrostatic Powder Coating Range

We offer five fluoropolymer options for electrostatic powder coating: PTFE (F4), PFA, FEP (F46), ETFE (F40), ECTFE (Halar, F30), and PVDF. - Fluoropolymer Emulsion Coating Options

Our emulsion-based coating services include PTFE, PFA, and FEP (F46) to meet different performance and process requirements.

The number of coating layers applied depends on the required thickness.

- 9. Sixth Topcoat Layer (cured at high temperature)

- 8. Fifth Topcoat Layer (cured at high temperature)

- 7. Fourth Topcoat Layer (cured at high temperature)

- 6. Third Topcoat Layer (cured at high temperature)

- 5. Second Topcoat Layer (cured at high temperature)

- 4. First Topcoat Layer (cured at high temperature)

- 3. Primer Layer (base coat applied and oven cured)

- 2. Surface Preparation (sandblasting)

- 1. Steel Substrate

Selection Guide of Fluoropolymer Coating

| Corrosion Protection Grade | Process Selection | Corrosion Protection Thickness | Typical Color | Raw Material Brand | Purity Grade |

| Fluoropolymer Coating for Industrial Applications | PTFE (F4) coating | 10μm-70μm | Green/Grey/Black/Brown… | Chemours/DuPont (USA) Daikin (Japan) Solvay (USA) | G1-G2 G1-G3 |

| PFA coating | 10μm-2000μm | Red/Black/White/Grey… | |||

| FEP (F46) coating | 10μm-1500μm | White/Black/Green… | G1-G2 | ||

| ECTFE (30,Halar) coating | 0.2mm-1.5mm | White/Black/Green… | G1-G3 | ||

| ETFE (F40) coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PVDF coating | 0.2mm-1.5mm | Beige/Black… | G1-G3 | ||

| PFA anti-static coating | 10μm-2000μm | Red/Black/White/Grey… | G1-G3 | ||

| ETFE (F40) anti-static coating | 0.2mm-1.5mm | Blue/Grey/White/Green… | G1-G3 | ||

| PTFE (F4) anti-static coating | 10μm-70μm | Green/Grey/Black/Brown… | G1-G2 | ||

| Fluoropolymer Coating for Semiconductor Manufacturing | PFA high purity coating | 10μm-2000μm | Black/Beige/Transparent… | / | 0.5~1ppb |

| ECTFE (30,Halar) high purity coating | 0.2mm-1.5mm | Black/Green…. | Solvay (USA) | ||

| PVDF coating | 0.2mm-1.5mm | Black/Beige/Transparent… | Arkema (France) | ||

| PFA high purity anti-static coating | 10μm-2000μm | Black/Beige/Transparent… | / |

Spray Coating Process Flow

- Incoming inspection

- Sharp edges grinding and smoothing

- Thermal degreasing and stress relief

- Grit blasting and roughing

- Surface roughness measuring

- Grit blasted surface cleaning

- Substrate pre-heating

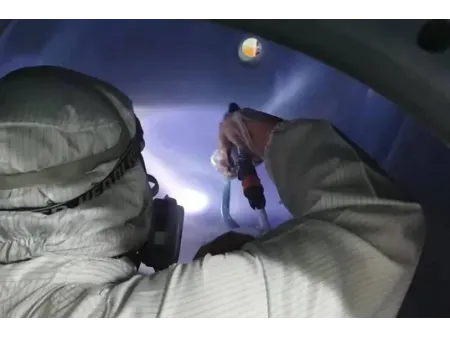

- Primer spraying

- Intermediate coat spraying

- Topcoat spraying and sintering for multiple times

- Coating appearance inspection

- Adhesion testing

- Coating film thickness measuring

- Holiday spark test

- Surface cleaning

- Packaging

We Provide Expert Coating Applications

- Welding of vessel structure

- Edge grinding & surface smoothing

- Sandblasting & roughness inspection

- Personnel air shower

- Equipment air shower before coating

- Primer spraying

- Intermediate coat spraying

- Topcoat spraying

- Adhesion testing

- Coating thickness inspection

- Holiday spark test

- Hydrostatic insulation test

Fluoropolymer Coating & Lining Services

Interested in our fluoropolymer coating & lining solutions?

Contact us today to explore how our customized protection technologies can meet your corrosion resistance and purity protection requirements.