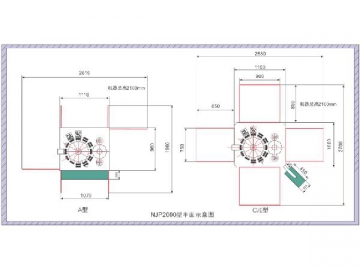

Capsule Filling Machine, Type NJP-2000, 1800, 1500

During the design process of the NJP-2000,1800,1500 automatic capsule filling machine, WISELY changed the orbiting angular velocity of the indexing box from 36° to 30°. This increased the stability of the machine.

Dual air supply technology

Dual air supply technology Ultra-low workstation turntable

Ultra-low workstation turntable Wrought grooved cams replace the springs

Wrought grooved cams replace the springs

| Machine Model | NJP-2000 | NJP-1800 | NJP-1500 |

| Max Output | 120000capsule/h | 108000capsule/h | 90000capsule/h |

| Suit for Capsule Size | 00#-5# and secure capsule A-E | 00#-5# and secure capsule A-E | 00#-5# and secure capsule A-E |

| No. of Mold Bores | 18 | 16 | 14 |

| Machine Dimensions (excluding the electric control cabinet) | 1120×970×1950mm | 1120×970×1950mm | 1120×970×1950mm |

| Net Weight | 1600kg | 1600kg | 1600kg |

| Power | 380/220V 50/60Hz 10kw | 380/220V 50/60Hz 10kw | 380/220V 50/60Hz 10kw |

| Noise | < 75dB | < 75dB | < 75dB |

- The machine features wrought grooved cams in its transmission mechanism instead of springs, so this capsule filling machine has longer service life.

- Fully closed workstation turntable is equipped with an automatic lubrication device, which can reduce the frequency of machine maintenance.

- It adopts a 10.4-inch colorful LCD display screen. The device can automatically alarm or stop operating in case of capsule shortage, powder shortage, vacuum malfunction, dust absorption fault and in the case of a loose machine door

- SEW motor and Schneider electrical components. It has bearings and a high-precision intermittent indexing box, and the distance between its input shaft and output shaft increase from 83mm to 145mm, which increases the performance of the control mechanism and transmission mechanism more stable.

- There are twelve steps in its capsule feeding mechanism, which can finish the filling process of medicine powders and pellets. During the indexing box's orbiting process, the angular velocity of the angle change from 36° to 30°, so the operation is more stable.

- The capsule filling machine and the motor are set separately. This makes the equipment safer and easier to clean.

- The operator can quickly finish cleaning and mold replacement during the cleaning process.

WISELY offers a wide range of pharmaceutical machinery like capsule filling machines, tablet polishers, and pharma packaging machines. The company was founded in 1992 and is a member of the China Association for Pharmaceutical Equipment. We participate in continuous development and have many patents for technologies used in our capsule fillers. We provide customers with high quality pharmaceutical and medical equipment all over the world.

Related:

Medicine Packing Machine, Powder Capsule Filling Machine, Automatic Capsule Filler, Pharmaceutical Equipment, Capsule Filling Equipment, Capsule Filling Line, Pill Capsule Filling Machine, Capsule Filling Device, Pharmaceutical Packaging and Filling Machine