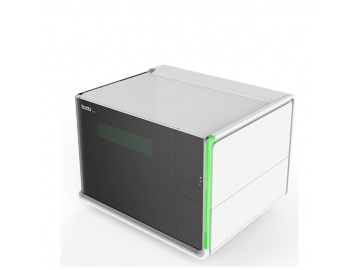

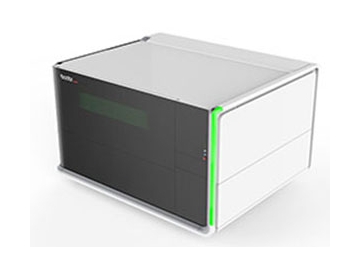

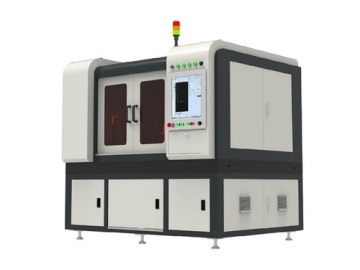

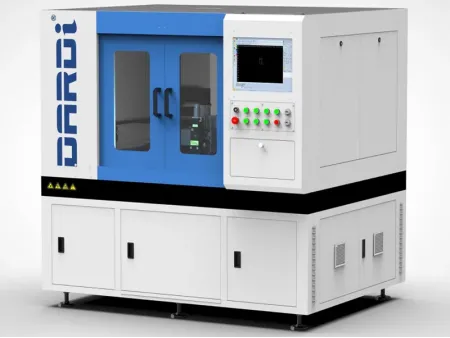

Precision Laser Cutting Machine i5

Fiber Laser Cutter, Fiber Laser Cutter System

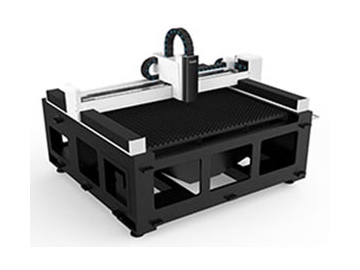

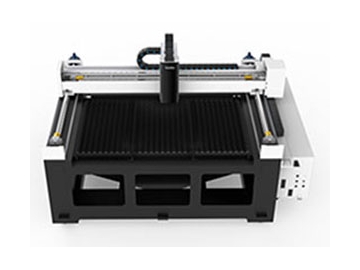

The i5 precision laser cutting machine can be used for precise cutting of carbon steel, stainless steel, aluminum, copper and some other alloy metal plates. The cutting width can be 900mm×1300mm. And the machine can be moved flexibly so that the utilization of space is the most effective.

The i5 is fully enclosed as protection which can fully isolate smoke and laser radiation. The safety is higher. Meanwhile, the pollution can be reduced to the minimum. Single phase power supply can keep smooth running of the machine. The power supplying is easy so the machine has wider suitability.

- Cast iron machine body

The i5 precision laser cutting machine body is made of carbon structural steel which features good toughness, plasticity, welding performance and hot workability. The material is treated by destressing, annealing and vibration aging so that the lathe is more stable. And the precision of the lathe can be kept for 20 years.

- Cast aluminum cross beam

The cross beam is made of aluminum alloy. The material features light weight and high rigidity. And the beam is fabricated by die-casting. And then there are some subsequent processes such as artificial aging and solution treatment so that the rigidity and toughness of the cross beam can be further increased. The solid and durable cross beam can be suitable for high speed running during processing. It can realize high speed and flexible cutting of different patterns when meeting the requirements of precision.

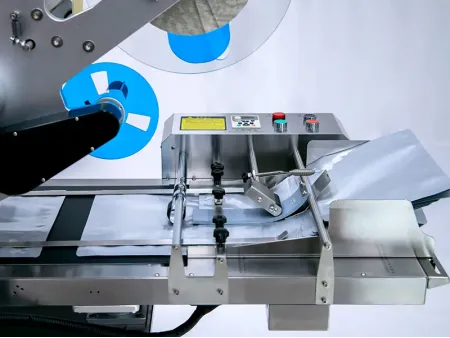

- Auto Focus laser head

With the auto focus laser head, the i5 laser cutting machine is suitable for different focal length. The focal length is controlled by the control system of the machine body. The focal point can be automatically adjusted during the cutting process which means that it can realize best cutting of plate material of different thickness. Meanwhile, there is no need of manual adjustment so that the miss and error caused by manual operation can be effectively avoided.

The laser head is equipped with build-in dual water cooling structure which can be used to prevent overheat of lens, thus increasing service life. The entire laser head is fully enclosed for better protect its parts. Besides, there is additional collimating lens protector and focal lens protector which ensures the safety of machine parts and human life. - High speed perforating

The i5 cutting machine adopts Bodor lightning technique so the perforating time is short. It can save 90% of the perforating time. For different material and plate thickness, when Bodor lightning is combined with manual focus laser head, the focal length should be adjusted manually so the efficiency is low; while it is combined with auto focus laser head, the data stored in the system can be automatically read so the efficiency is high. Perforating focal length is added. And the perforating focal length and cutting focal length can be set separately so that the cutting can be more accurate.

- Bodor Pro 2.0

Bodor Pro 2.0 is the self-developed operation system which can realize intelligent typesetting of cutting patterns. It supports multi-graphics import, automatic cutting sequence optimizing, intelligent edge-searching and automatic positioning. For controlling, we select the best logic programming and software interaction to effectively improve material utilization and reduce wastes. The simple and fast operation system can effectively and accurately give cutting instructions which improves customer experience.

- Auxiliary gas low pressure alarming function

i5 laser cutting machine provides real-time pressure inspection. When the pressure is lower than that can provide best cutting effect and precision, the machine will send the information of abnormal status so that the gas supply can be replaced timely thus ensuring good cutting effect and precision.

- WIFI remote and intelligent assistance

The WIFI remote and intelligent assistance can realize global real-time feedback, providing real time failure analysis and trouble shooting.

- Intelligent stroke protection

The stroke of cross beam and cutting parts will be automatically monitored to ensure that the operating position of these parts are within the processing range. It is also equipped with fixing and limiting functions which greatly improves the safety of machine and human life.

- Automatic lubricating system

The automatic lubricating system provides quantitative lubricating oil for laser cutting machine regularly to ensure its smooth and high speed running. This system is also equipped with abnormity warning and liquid level alarm functions. It greatly increased the cutting precision and prolonged the service life of transmission mechanism.

- Safety following module

During cutting of material, the space between laser head and workpiece will be kept at any time to reduce the risk of collision. i5 is also equipped with automatic stop function after collision to reduce accident rate.

- Intelligent alarm system

This intelligent alarm system provides comprehensive abnormity alarm function. It will also show the information on the interface via control center so that operator can notice the abnormity of the machine previously, reducing hidden danger.

| Model | i5 |

| Working Area | 1000*1500mm |

| Laser Power | 4000w/3000w/2000w/1500w/1000w |

| X/Y-axis positioning accuracy | 0.03mm |

| X/Y-axis repositioning accuracy | 0.02mm |

| X/Y-axis Max. linkage speed | 60m/min |