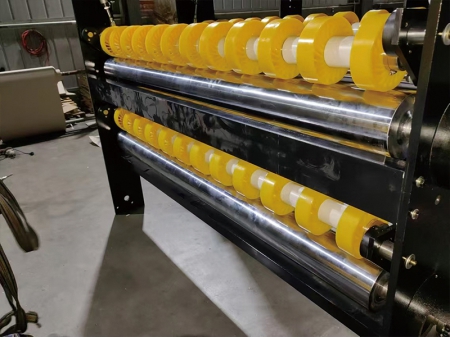

Double Layer Cutting Machine

Request a Quote

-

- Max. machine speed

- 100 - 180m/min

-

- Paper cutting range

- 500-9999mm

-

- Cutting precision

- ±1mm (at steady speed)

Features

- The cutting machine features a reinforced wall plate and a heavy-duty base, providing excellent structural rigidity. Transparent viewing windows on both sides of the wall plate allow operators to monitor the cutting process with ease.

- The transmission system uses an automatic oil-pump circulation lubrication setup, supported by an independent pump and filtration unit to ensure clean, reliable, and continuous lubrication of all moving components.

- The helical knife shaft is manufactured on a fully automated machining center, delivering high accuracy and smooth performance even during high-speed cutting operations. All gears are made from premium alloy steel and undergo quenching, carburizing, and precision grinding, achieving a hardness of HRC 58–60° for superior durability and stability.

- The intelligent control system automatically adjusts the cutting acceleration according to board specifications and production speed. It continuously tracks the running speed of the board to maintain perfect synchronization throughout operation.

- For enhanced production flexibility, the system can store up to 999 orders and execute them sequentially or by priority, enabling seamless and efficient automated order changeovers.

Specifications

| Cardboard requirements | Base paper | < 360g/㎡ | Core paper | < 200g/㎡ | |||

| Thickness | 3 - 14mm | Moisture content | < 10% | ||||

| Angularity | < 30mm | ||||||

| Relative humidity | 20%-90% | Ambient temperature | 5℃ - 50℃ | ||||

| Air source pressure | 0.6 - 0.9MPa | ||||||

| Cutter shaft diameter | Upper | Ø200mm | Lower | Ø200mm | |||

| Guide roller diameter | Upper-front (no-crush corrugator wheels) | Ø165mm | Lower-front | Ø155mm | |||

| Upper-back | Ø165mm | Upper | Ø155mm | ||||

Related Corrugating Machinery