Vacuum Mixing Emulsifier

Request a Quote

ZRX-30/50

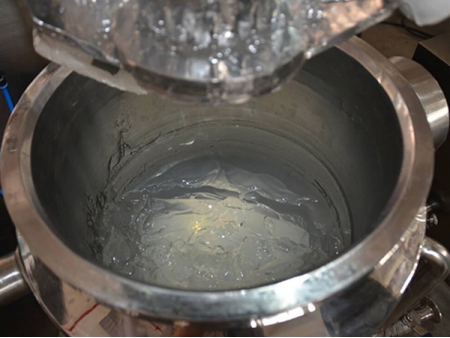

Our advanced vacuum mixing emulsifier is designed for the production of creams, emulsions, and pastes across industries such as pharmaceuticals, cosmetics, food, and chemicals. This mixing equipment is a highly efficient and versatile tool, tailored to meet the demands of today’s quality-driven production environments.

This vacuum mixing emulsifier includes an emulsifying tank, oil-phase and water-phase storage tanks, a vacuum system, hydraulic system, and an electric control panel—ensuring seamless integration and optimal functionality throughout your production process.

Technical Specifications

| Model | | | |

| Emulsification Container | Container Volume | 50L | 80L |

| Working Volume | 30L | 50L | |

| Permissible Working Pressure | Inner tank: -0.1MPa, Jacket: 0.1MPa | ||

| Permissible Working Temperature | ≤100°C (Inner tank: ≤120°C, Jacket: ≤100°C) | ||

| Slow-Speed Frame Type Agitator | Rotation Speed | 0-60r/min (variable frequency speed control) | |

| Power | 0.37kW | 0. 75kW | |

| High-Speed Homogenizer | Rotation Speed | 0-3500r/min (variable frequency speed control) | |

| Power | 1.5kW | ||

| Vacuum Degree Inside Tank | -0.097MPa | -0.098MPa | |

| Medium-Speed Dispersing Agitator | Rotation Speed | 0-960r/min (variable frequency speed control) | |

| Power | 1.5kW | ||

| Vacuum Pump | Model | 2BV2060 | |

| Power | 1.1kW | 0.81kW | |

| Type | Liquid Ring Vacuum Pump | ||

Features

- All parts in contact with materials are made of SUS316L stainless steel with a mirror-polished interior and exterior, fully meeting GMP standards for hygiene and durability.

- Equipped with fully automated controls and pipelines from leading brands like Siemens and Schneider, mixing machine ensures stable, reliable operation and precise adjustments.

- Easy Cleaning with CIP System: The emulsifying tank is fitted with a CIP (Clean-in-Place) system, offering efficient and thorough cleaning, essential for maintaining hygiene standards with minimal downtime.

- Three-Stage Stirring in a Vacuum Environment: With a three-stage stirring system that operates within a vacuum, the emulsifier prevents foam formation and contamination, optimizing the purity and consistency of your products.

- Advanced Homogenizing Technology: The high-speed homogenizer reaches up to 0-3500r/min, with low-speed stirring adjustable up to 0-65r/min, offering versatility for different production requirements.

Safety protection measures

- The lifting mechanism is disabled when discharging materials, preventing any potential collision between the stirring device and the emulsifying tank.

- The tank cover cannot tilt unless it has been fully raised to the highest position, safeguarding against accidental contact with the stirring device.

- During positive pressure discharge, a secure latch connects the tank body to the cover, and the lifting mechanism is deactivated to prevent movement.

- When the vacuum system is active and the tank is under negative pressure, the lifting mechanism is locked to maintain the system safe and stable.

- Once the tank cover is raised, the stirring mechanism is automatically disabled, reducing the risk of operator injury.