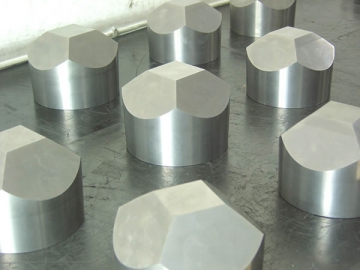

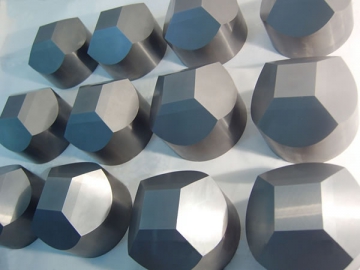

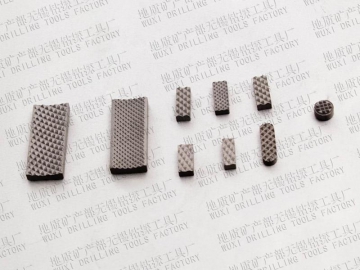

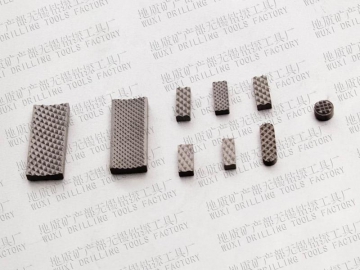

Carbide Anvils (for Synthetic Diamond Industry)

Synthetic Diamond Carbide Anvils / Carbide Anvils / Tungsten Carbide Anvils

Summation of Technology and Production Experience

1. Ultimate tungsten carbide technology and experience

2. Durable for extreme high temperatures and pressure

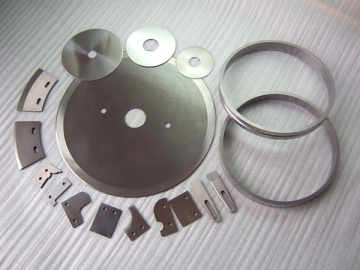

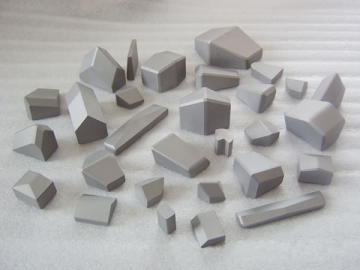

3. Precise machining for diamond, PCD and PCBN

4. More than ISO9001 and ISO14001 standards

5. Extreme diamond manufacturing technology

6. Tungsten carbide technology required to manufacture anvils and dyes

7. Durable: service life of 2,000 1 hour pressuring cycles at 1,500° and 5,000 bars.

8. Precise machining experience

9. Fine powder mixture control

10. More critical pressure: up to 60,000 bars

11. Milling and grinding experience for diamond, PCD and PCBN

| Grade | Co(%) | Density (G/Cm3) | Hardness (HRA) | TRS (N/mm2) |

| JN8 | 8.0 | 14.70 | 91.0 | 3500 |

| JA10 | 10.0 | 14.50 | 91.2 | 3800 |

Packaging and Delivery

Packaging Details: Carton and plywood case, making it suitable for international delivery via air or sea.

Precautions for Use:

1. Eliminate the residual stress on the carbide anvil after forming. Before using the carbide anvil, an aging treatment should be carried out, including natural aging, oven aging, boiling oil aging, vacuum aging and ultrasonic aging. The natural aging time should be no less than a month, and the aging oven temperature should be under 250°C for a period of no less than 72 hours.

2. Anvil Assembly Requirements

The taper on the anvil should be the same as that of a steel ring. The contact surface is ˃90%. The press fitting height should also be reasonable. Under cM27mm, the press fitting height is 8-10mm, and above cM27mm, the press fitting height is 10-12mm. There should be no point contact between the anvil and the spacer blocks to avoid stress concentration.

3. Requirements for Raw and Auxiliary Materials

The machining precision of the steel ring and spacer blocks should meet all requirements. The smooth finish of the inner wall of the steel ring must achieve Ra1.6. The roundness and taper should conform to the tolerances of the form and position of the anvil. The depth of parallelism of large and small spacer blocks is ˂0.02mm. The hardness is moderate. Pyrophyllite calcination temperature and time should be moderate, in order to prevent blowouts caused by poor pressure carrying performance pressure and a high moisture rate. The surface of the conductive steel ring is rust resistant, and the edge has no cracks. There is no discoloration phenomenon, even after baking. Please pay attention to moisture resistant storage.

4. Requirements for Equipment

The press should have an excellent adjusting accuracy, and leaks are prohibited. The synchronization and centering tolerance is no more than 0.2mm.