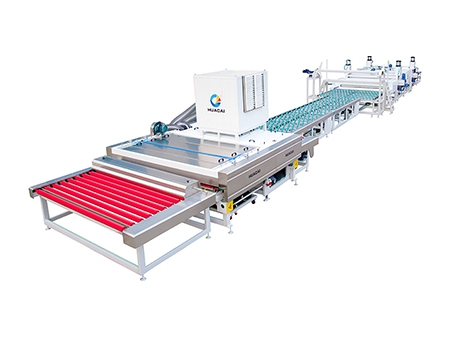

Conveyor Idlers / Rollers

Also known as conveyor roller, conveyor idler is the component that a conveyor uses the most. It is one of the major factors affecting operation stability of the conveyor. Its service life also plays a major role in determining operating cost of the conveyor.

Since idler is such an important part for conveyors, we have spent many years in studying how to produce better ones. We have been able to develop our own unique high efficient and reliable production process, which ensures our idlers with high accuracy, long service life and great sealing effect.

Features

1. Our idler has high rotation flexibility. After assembly, it is able to rotate at speed of 600r/min when imposed upon radial pressure of 250N. Its rotation resistance is no greater than 2.5N. Hence, it is capable of reducing electricity consumption of its own and avoiding tape tearing and motor burnout at the same time.

2. Our idler also features excellent sealing effect. It is able to ensure that no dust will enter its bearing housing even after 200 hours of rotation in a dust box. In addition, the water seeping into the idler chamber will be less than 5g after the idler is completely immersed into water for 24 hours.

3. Our idler has high axial bearing capacity. Even drop ped from one meter above the cement ground vertically, the idler is able to prevent axial displacement. When imposed with axial pressure of 500N, the idler will only allow axial displacement less than or equal to 0.4mm.

4. Our idler can fully ensure stable operation. Radial circular run-out of our idlers (except special kinds such as impact idler and comb idler) is no greater than 0.5mm when the idler length is less than or equal to 550mm and the conveyor belt speed is greater than or equal to 3.15m/s. Therefore, our idler is capable of ensuring stable operation of belt conveyors, thereby eliminating resonance of the belt and further preventing material spill and protecting environment.

5. Our idler is also assured with low failure rate. We promise that the failure rate of our AH branded idlers won't exceed 10 percent within 50,000 hours of working under normal conditions.

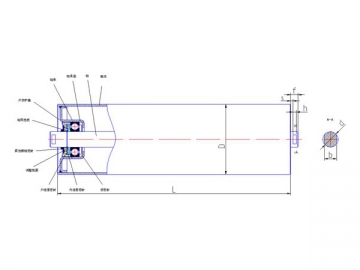

Structure

1. A flexible contact seal is adopted at the position where the idler shaft is installed between two relatively rotating elements to ensure that foreign matter won't enter the bearing housing and the idler chamber. In this way, probability of idler damage will be significantly reduced. In addition, the position is where we have the smallest contact area between these two rotating elements. Hence, rotating resistance reaches the minimum at the position.

2. Moreover, an external protective hood is also utilized to protect the seal from damage caused by external impact.

3. An axial spring collar is placed between inner and outer seals to prevent them from rubbing against each other. The spring collar is relatively closer to the bearing, which contributes to high axial bearing capacity and great axial impact resistance.

Applications

Our idlers are designed to carry goods and support conveyor belts. The goods carried can be items or bulk materials. Bulk density of the carried stuff is ranging from 500 to 2,500kg per cubic meter. Working temperature of our idlers varies from -20℃— 40℃. Our idlers are extensively applied for material transportation in many fields including metallurgy industry, coal industry, transport industry, electric plants, building materials industry, chemical industry, light industry, grain industry and mechanical industry.

| D | L | Bearing Type | d | b | h | f | Weight (kg) |

| 89 | 200 | 6204/C4 | 17 | 12 | 6 | 14 | 2.08 |

| 250 | 2.15 | ||||||

| 315 | 2.58 | ||||||

| 465 | 3.8 | ||||||

| 500 | 4.1 | ||||||

| 600 | 4.78 | ||||||

| 750 | 5.79 | ||||||

| 950 | 7.15 | ||||||

| 108 | 250 | 6205/C4 | 25 | 18 | 8 | 17 | 3.01 |

| 315 | 3.53 | ||||||

| 380 | 4.07 | ||||||

| 465 | 4.77 | ||||||

| 530 | 5.32 | ||||||

| 600 | 5.89 | ||||||

| 700 | 6.56 | ||||||

| 750 | 7.14 | ||||||

| 800 | 7.33 | ||||||

| 950 | 8.78 | ||||||

| 1150 | 15.2 | ||||||

| 1400 | 18.11 | ||||||

| 1600 | 20.7 | ||||||

| 133 | 250 | 6305/C4 | 25 | 18 | 8 | 17 | 6.06 |

| 315 | 7.12 | ||||||

| 380 | 8.13 | ||||||

| 465 | 9.62 | ||||||

| 530 | 10.7 | ||||||

| 600 | 11.86 | ||||||

| 670 | 12.95 | ||||||

| 700 | 13.53 | ||||||

| 750 | 14.26 | ||||||

| 800 | 15.17 | ||||||

| 900 | 16.77 | ||||||

| 950 | 17.66 | ||||||

| 1000 | 18.36 | ||||||

| 1100 | 20 | ||||||

| 1150 | 20.98 | ||||||

| 1250 | 22.48 | ||||||

| 1400 | 25 | ||||||

| 1600 | 28.48 | ||||||

| 1800 | 31.58 | ||||||

| 2000 | 6305/C4 | 25 | 18 | 8 | 17 | 34.9 | |

| 2200 | 38.26 | ||||||

| 2500 | 43.24 | ||||||

| 159 | 315 | 6306/C4 | 30 | 22 | 8 | 17 | 10.39 |

| 380 | 11.87 | ||||||

| 465 | 13.8 | ||||||

| 530 | 15.27 | ||||||

| 600 | 16.86 | ||||||

| 670 | 18.35 | ||||||

| 700 | 19.13 | ||||||

| 750 | 20.16 | ||||||

| 800 | 21.4 | ||||||

| 900 | 23.58 | ||||||

| 950 | 24.7 | ||||||

| 1000 | 25.86 | ||||||

| 1100 | 28.06 | ||||||

| 1150 | 29.34 | ||||||

| 1250 | 31.51 | ||||||

| 1400 | 35.02 | ||||||

| 1600 | 39.56 | ||||||

| 1800 | 44 | ||||||

| 2000 | 48.53 | ||||||

| 2200 | 53 | ||||||

| 2500 | 59.91 | ||||||

| 2800 | 66.65 | ||||||

| 194 | 600 | 6307/C4 | 35 | 26 | 10 | 20 | 26.2 |

| 670 | 28.5 | ||||||

| 750 | 31.2 | ||||||

| 800 | 32.8 | ||||||

| 900 | 36.1 | ||||||

| 1000 | 39.4 | ||||||

| 1100 | 42.7 | ||||||

| 1250 | 47.6 | ||||||

| 1400 | 52.6 | ||||||

| 1800 | 65.7 | ||||||

| 2000 | 72.6 | ||||||

| 2200 | 78.8 | ||||||

| 2500 | 88.7 | ||||||

| 2800 |

Our company provides varieties of idlers including raceway idler, impact idler, polyurethane idler, spiral idler, friction idler, comb idler, conical idler, etc.

Raceway idler is widely applied to support and deliver flat belts. It features great transportation stability.

Impact idler is able to lend a belt conveyor additional support at loading points where the belt is subjected to considerable impact stress. It is one of Class I idlers, which is specially designed for corrosive environments such as coal washery, coking plants and chemical plants.

It features excellent anti-corrosion performance. Its service life will be five times more than that of a regular idler when working in corrosive environments. In addition, its tenacity is ten times higher than that of common metals. Furthermore, impact idler can withstand static electricity and won't damage the belt. With all these merits, it is also widely applied for mining.

Most of polyurethane idlers are made through casting process, which means coating steel or iron idlers with polyurethane elastomer. This kind of idler is characterized by high resilience, great wear resistance and outstanding tear resistance. In addition, it has longer service life than steel idlers or common rubber.

Spiral idler functions the same as a sweeper. It is used to remove the sticky materials attached on the delivering surface. Generally, it will be applied as the nearest return idler to the head pulley of a conveyor.

Friction training idler is utilized to automatically correct belt offset accumulated during operation to ensure normal and stable operation of the belt conveyor.

Comb idler or sleeve idler is exclusive for conveyors used for delivery of sticky materials.

Conical idler features great wear resistance, light weight, long service life, small rotatory inertia, reasonable structure, reliable sealing effect and excellent anti-corrosion performance. It can be divided into conical training load idler and conical training return idler.