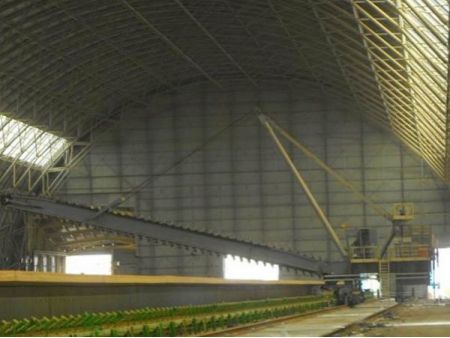

Side Type Scraper Reclaimer

Request a Quote

The tracked reclaimer can homogenize various materials, such as alumina, clay, ironstone, raw coal and more. We offer two types of stacker and reclaimer equipment, with a 300 ton/hour and 200 ton/hour capacity. This stockyard system is widely used in cement and building materials, coal, electricity, metallurgy, iron, chemical and other industries.

Technical Parameters

| Model | Capacity (Max) | Outlet belt width | Rails gauge | Rail type |

| 300t/h | 800mm | 4m | discharge side rail type QU120 | |

| opposite side rail type QU100 | ||||

| 200t/h | 800mm | 4m | discharge side rail type QU120 | |

| opposite side rail type QU100 |

Structure and function

- Scraper chain

It can be used for both horizontal and inclined transportation. - Hoisting system

the hoisting system is comprised of an electric hoist, pulley, wire rope and steel structural support. Equipment lifting is carried out by an electric hoist, thus allowing the scraper chain to be inclined at a suitable angle for material collection. - Feeding hopper

The discharging end is designed with , [GF1] and the discharge belt bypasses the impact idlers on the loading pulley in order to achieve a blanking buffer. The use of impact idlers can reduce impact on the discharge belt conveyor. - Operator cab

The operator cab is mounted on the steel structural support, and is equipped with an interior PLC system and electrical cabinet. - Counterweight

A counterweight is used to balance the reclaimer and prevent it from falling over.

- Travelling mechanism

- Platform

- Cable reel

Features

- Structural design

SINOMALY has the ability to independently design and produce large-scale mining equipment and cement equipment. The overall design process of the side boom reclaimer meets the requirements for different working conditions, thus ensuring the reclaiming capacity and storage requirements are met. We can also customize this equipment to match specific stockyard conditions. - Reliability

Computer aided design, three-dimensional design and steel structure optimization are used to assist in the design of the side boom reclaimer structure. SINOMALY has a steel pretreatment production line, which can improve the corrosion resistance of structural parts and ensure the quality of all finished products. The use of large milling machines increases the working accuracy of large components. In the factory, the structure is assembled as a whole, the driving system is debugged and the slewing mechanism is made using a mold.

SINOMALY uses high-performance new materials such as wear-resistant materials and composite materials to improve the durability of the bulk material handling equipment.

Soft start and variable frequency control are used in order to reduce reclaimer damage caused by heavy impacts. Protective measures have been set up on the side boom reclaimer, which can automatically adjust or stop when abnormal conditions occur. - High efficiency and flexibility

This stockyard system is automatically operated to achieve an automatic material stacking and reclaiming. Several operation modes for material stacking and reclaiming are set up to fully meet the requirements of different stockyard working conditions.