Shrink Sleeve Labels

Zhongheng has over 10 years of experience in plastic labeling and run eight advanced production lines dedicated to shrink sleeves. All the production stages, including printing, lamination, die-cutting, inspection, and packaging, are managed in our own facilities, giving us better control over quality and delivery times.

Our stock of raw materials gives us the flexibility to handle urgent requests as well as large orders. Customers can choose from different label materials such as PVC, PETG, and OPS, depending on their requirements for the appearance of their finished products, environmental performance, or cost control. After shrinking, the labels fit closely to bottles and containers of different shapes, including curved and irregular ones. The result is a smooth finish without wrinkles or bubbles, showing the full shape of the container while also protecting the product.

| Material type | PETG, PVC, OPS |

| Thickness | 35–70 μm |

| Layflat width | 50–300 mm |

| Slit width | 100–600 mm |

| Label height / cut length | 30–300 mm |

| Core inner diameter | 76 mm (3 in.) |

| Shrinkage (TD) | 40–80% |

| Shrinkage (MD) | 0–10% |

| Shrink temperature range | 90–110 °C |

| Tensile strength | ≥ 40 MPa |

| Tear resistance | ≥ 70% |

| Transparency | ≥ 90% |

| Haze | ≤ 10% |

| Printing methods | Gravure, flexo, digital |

| Color options | Over 10 colors available |

| Surface finish | Glossy, matte, coated |

| Easy-tear / perforation | Optional |

| Anti-scratch coating | Optional |

| Environmental Features | Recyclable / Biodegradable |

- The film (PETG, PVC, OPS) used to manufacture the shrink sleeve has high transparency, which makes printed colors look bright and shiny on the label.

- Instead of being made together with the product, shrink sleeves are produced separately in large runs. This makes it easier to manage inventory and apply them on different packaging lines.

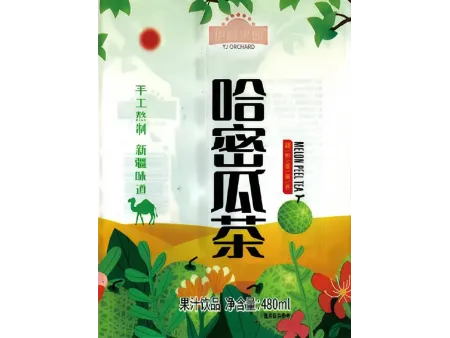

- Once shrunk, the label wraps tightly around the container, showing its shape and giving the package a clean look. When used on specially shaped bottles, the sleeve follows the curves of the container, giving the package a lively look that attracts children.

- The material used for shrink sleeves is durable enough to handle daily use and the weight of the product. The graphics are printed inside the film, which keeps them safe from scratches and easy to read.

- The labeling process is simple. Thanks to the film’s heat-sealing properties, the labels can be applied without adhesives.

- As modern packaging often uses unusual shapes, shrink sleeves are used because they adjust easily to different forms.

Shrink sleeve labels are designed for a wide range of packaging needs. They are commonly used for:

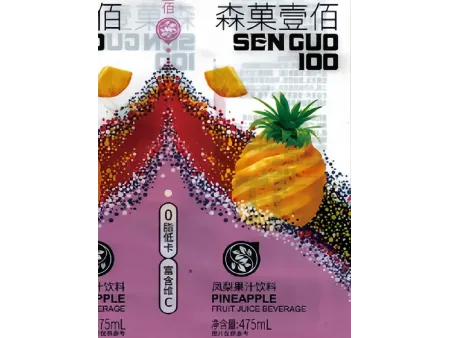

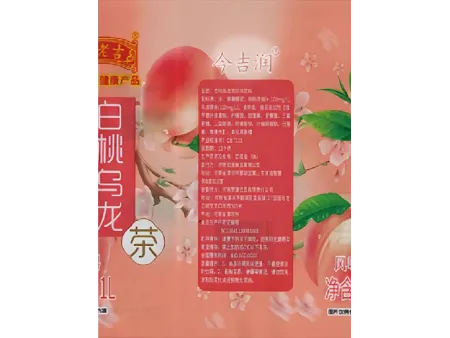

- , including carbonated drinks, juices, energy drinks, and other functional beverages.

- , such as bottled water, beer, and similar products.

- , including milk, yogurt, milkshakes, and other dairy-based beverages.

- , such as shampoo, body wash, laundry detergent, cleaning products, and cosmetics.

- , including soy sauce, vinegar, chili paste, ketchup, and other seasonings