Wear Parts for Concrete Equipment

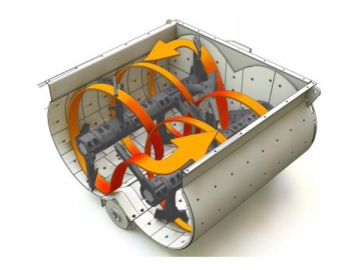

The concrete batching plant wear parts include the mixer blade, mixing arm, wear liner, scraper, spacer ring and other parts, all made using chromium alloy and Ni-CR alloys that have undergone quenching and tempering as the raw materials. These alloys reach a hardness of 68 HRC and have a service life of 200,000 uses. We are also outfitted with an automatic molding line to reduce the need for manual labor, improve production, and shorten the delivery period.

Mixer blade

Available brands

Sicoma: planetary mixers, twin shaft mixers, continuous mixers, Portable mixers

BHS: planetary mixers, twin shaft mixers, twin shaft continuous mixers, single shaft mixers

Liebherr: Compact mix 0.5, Compact mix 1.0, Betomix2.25, Betomix2.5, Betomix3.0

KYC: EX mixer, twister and tornado

Teka: Pan mixer, turbine mixer, planetary mixers, twin shaft mixers

Conele: planetary mixers, twin shaft concrete mixers, portable mixers

Raw material

Standards of cast steel: DIN, JIS, EN, ASTM, GB

Chromium alloy: 5%-30% Cr. Hardness: 45-68HRC

Ni-Cr alloy: 3%-7%Ni, 1.5%-9%Cr. Hardness: 45-68HRC

1. Send the sample or drawing to Huadong

2. Mold making

3. Mold testing

4. Mass production

5. Component testing

6. Heat treatment

7. Hardness testing

8. Polishing

9. Spray painting

10. Packaging

Advantages

1. We have 20 years of casting experience and 50 technicians to meet various customer requirements.

2. Equipped with a 3D scanner, we are able to create precise drawings of customer products.

3. Equipped with a SPECTRO spectrometer, we can test the chemical components of each product in a precise manner.

4. An advanced lost foam casting line and automatic molding line are used in the production of our wear resistant parts, which allows us to meet the requirements for mass production and short delivery periods.

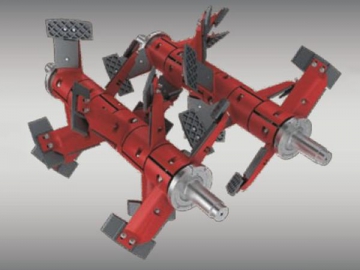

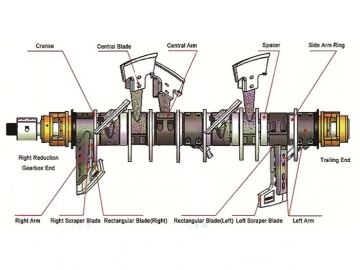

Concrete Mixing Shaft Arm for Concrete Plant, Sicoma Concrete Equipment

Concrete Mixing Blade for Concrete Plant, Sicoma Concrete Equipment

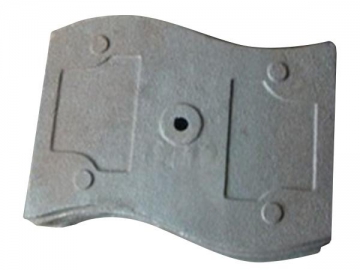

Concrete Mixing Liner Plate for Concrete Plant, Sicoma Concrete Equipment

Concrete Mixing Spacer for Concrete Plant, Sicoma Concrete Equipment

Concrete Mixing Shaft Arm for Concrete Plant, BHS Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, BHS Concrete Equipment -

Concrete Mixing Liner Plate for Concrete Plant, BHS Concrete Equipment -

Concrete Mixing Scraper Plate / Lateral Plate for Concrete Plant, BHS Concrete Equipment

-

Concrete Mixing Arm Protector for Concrete Plant, BHS Concrete Equipment -

Concrete Mixing Shaft Arm for Concrete Plant, Liebherr Concrete Equipment -

Concrete Mixing Liner Plate for Concrete Plant, Liebherr Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, Liebherr Concrete Equipment

-

Concrete Mixing Blade for Concrete Plant, Elba Concrete Equipment -

Concrete Mixing Liner Plate for Concrete Plant, Elba Concrete Equipment -

Concrete Mixing Shaft Arm for Concrete Plant, Elkon Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, Elkon Concrete Equipment

-

Concrete Mixing Liner Plate for Concrete Plant, Elkon Concrete Equipment -

Concrete Mixing Scraper Plate for Concrete Plant, Elkon Concrete Equipment -

Concrete Mixing Shaft Arm for Concrete Plant, KYC Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, KYC Concrete Equipment

-

Concrete Mixing Liner Plate Concrete Plant, KYC Concrete Equipment -

Concrete Mixing Shaft Arm for Concrete Plant, NFLG Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, NFLG Concrete Equipment -

Concrete Mixing Liner Plate for Concrete Plant, NFLG Concrete Equipment

-

Concrete Mixing Shaft Arm for Concrete Plant, Stetter Concrete Equipment -

Concrete Mixing Blade for Concrete Plant, Stetter Concrete Equipment -

Concrete Mixing Liner Plate for Concrete Plant, Stetter Concrete Equipment

Huadong, wear parts maker, manufactures wear part of heavy equipment like concrete plant wear parts, cement wear parts, asphalt plant wear parts, and other heavy equipment wear parts. We do not just provide regular wear parts for the heavy machines specified, we offer custom wear part service according to client requirements to fabricate all wear parts. Plenty of raw material and fully equipped machine and facilities of manufacturing wear parts for heavy equipment, we have listed several brands wear parts here, and they are stocked for any order for a long time, we ever made wear parts for heavy equipment of Sicoma, Liebherr, BHS, Elkon, Lintec, Marini, Benninghoven, etc. We started to make wear parts since 1999.

Index

Cast steel parts, alloy parts, concrete mixer parts, custom replacement parts