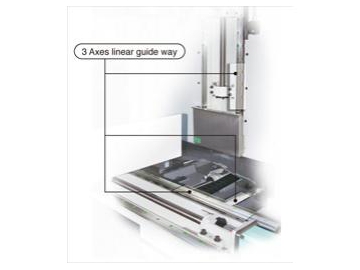

CNC Milling Machine(Linear guide way)

Request a Quote

This product has been discontinued and removed from our shelves.

Optional 16 tools armless type ATC for all models

Optional 16 tools armless type ATC for all models

The gap between the linear guides of the C-TEK CNC milling machine with linear guide way is small, so the machine has minimal friction and can process workpieces quickly. As a CNC machine with high processing precision, our CNC milling machine is suitable for small batch processing of molds, models and manufacturing tools.

C-TEK CNC milling machine can be equipped with 16 tools arm ATC or 24 tools armless ATC.

Features

1. Extremely rigid cast construction- The main casting including the bed, column, saddle, and table are constructed from high quality meehanite castings.

- The X Y Z axes employ linear guider with the feature of high rigidness low noise, low friction so that axes can move swiftly.

- The X, Y and Z axis employ ø32mm high precision ballscrews, coupled with a double nut design for precise traversing.

- Direct Motor Drive in all three axes.

- The surface accuracy is precisely inspected by laser calibration.

- There is no counter-balance block on the Z -Axis.

- Main function screen

- Contour simulation with taper finish

- Contour simulation with cutting point and cutway select for arc-in and arc-out

- PC Based Conversational Controller means that no previous programming experience is necessary, anyone can learn within a few hours of training with this question and answer format.

- Driven by high torque, low noise, high stability AC Digital servo motors and drives.

- The versatile C-Tek CNC Control offers high capabilities to handle easily many different types of component, from simple to the most sophisticated of jobs.

- Easy to use software with graphic input programming in basic machinist language, with non-complicated G & M codes.

- Powerful help function to assist users to edit complex geometry.

- It allows NC program to start run by any block when a tool breaks.

- 3D cam simulation

- Pocket style for spiral and taper finish

- Pocket style for spiral

- Pocket style for ZIG-ZAG

- Contour simulation with rotation and copy

Standard accessories

- Spindle speed 8,000 rpm (belt type)

- Table splash guard

- BT40 Power draw bar

- Toolbox & Manuals

- Frequency inverter

- Auto lube system

- Chip Tray

- Coolant system

- Halogen lamp

- Rigid tapping

- Ethernet

- TFT-LCD

Optional accessories

- Full enclosed splash guard

- 16 tools armless ATC

- 24 tools arm ATC

- Spindle chiller for 10,000 rpm (belt type)

- Spindle chiller for 10,000 rpm (direct type)

- Rotary table (fourth axis)

- Tilting table (fifth axis)

- CF card and adaptor boards

| CTN-830 Specifications and Function | |

| Simultaneous controllable axis: X.Y.Z.C.B axis | CPU : Industrial PC based 32-BIT |

| Interpolation: Linear for 3D, circular for 2D | Monitor : 15" TFT LCD |

| Coordinate system: Absolute, incremental | Floppy disk: 3.5" 1.44MB |

| Dwell : 0-9.9 sec for drilling | File storage: DOM or CF card |

| Least I/P dimension: 0.001 mm | Axis motor: digital AC servo motor for 3 axes |

| Max programmable dimension : /-9999.999 mm | Machining interrupt and return |

| Jog feedrate: 1um, 10um, 50um, 100um per pulse | Machining time display |

| Feedrate: 10-8000 mm/min | Program error display |

| Feedrate override: 10%-150% | Machine alarm display |

| Backlash compensation: 0-999um | Watchdog alarm display |

| Pitch error compensation: /-50 points | Break point setting |

| Tool compensation: /-999.999 mm | Standard G code edit |

| Mirror image: X, Y axis mirror | Standard M code edit |

| Rotation angle: 0-360 degree | 3D cam transfer interface |

| 2.5D Contour: cut way select, Taper | Network transmit : transfer rate 100MB/Sec. |

| 2.5D Pocket: Zig-Zag, Spiral, Taper | Look ahead : 1500 Block/Sec. |

| Linear array Nx, Ny: 1-999 | Automatic detect acc/dec speed of tiny R corner |

| Linear array Dx, Dy: /-999.999 mm | 3D program editing on line |

| Edit Line: ins/del | With motor parameters adjusting function to control the motor and machine in the best condition |

| Edit page: up/down | |

| Cutting path simulation | P.I.D.F Control Loop |

Parameters

| Model | KM-80L | KM-100L | KM-150L | KM-180L |

| Table | ||||

| Table surface | 1000*410mm | 1200*410mm | 1700*450mm | 2000*450mm |

| T-slot(W×N) | 18/3T | 18/3T | 18/5T | 18/5T |

| Table load capacity | 300kg | 350kg | 600kg | 600kg |

| Travels | ||||

| X travel | 800mm | 1000mm | 1500mm | 1800mm |

| Y travel | 500mm | 650mm | ||

| Z travel | 600mm | 650mm | ||

| Spindle center to column | 500mm | 635mm | ||

| Spindle nose to table | 115~715mm | 120~770mm | ||

| Spindle | ||||

| Taper of spindle nose | BT40 | BT40 | ||

| Spindle speed | 8000rpm | 8000rpm | ||

| Feed | ||||

| Rapid on X, Y & Z axis | 20,000mm/min | 15,000mm/min | ||

| Motor | ||||

| Spindle motor | 7.5HP | 10HP | 15HP | |

| Ac servo motor | X/Y=1kw,Z=2kw | 1.5kw | ||

| General | ||||

| Power required | 13KVA | 14KVA | 18KVA | |

| Net weight | 2830kgs | 3030kgs | 5000kgs | 5500kgs |

| Gross weight | 3230kgs | 3430kgs | 5400kgs | 5900kgs |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos