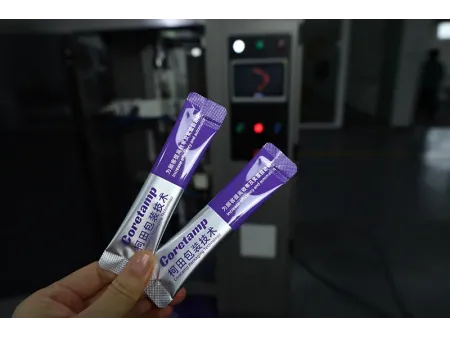

3&4 Side Seal / Back Seal Stickpack Powder Packaging Machine

Vertical Form Fill Seal Machines for Powdery Products

- Packaging Lanes

- 1-2

- Dosing System

- Auger Filler

- Packaging Speed

- 20-80 Cuts/min/Lane

- Film Roll Width

- Up to 240mm

- Stick Pack Size (Length × Width)

- 50-180mm × 50-140mm

Widely applicable across the pharmaceutical, food, cosmetics, and health supplement industries, this machine is perfect for packaging a variety of products. Examples include medicinal granules, probiotics, protein powders, meal replacement powders, spirulina powder, instant coffee, lotus root powder, tea powder, pearl powder, and seasonings.

- Coffee powder

- Probiotics

- Chinese medicine powder

- Fruit and vegetable powder

- Notoginseng powder

- Milk powder

- Milk tea powder

- Spirulina algae powder

Your ideal solution for single-lane or dual-lane packaging of loose powder products in pharmaceutical-grade health supplements. This machine features a custom screw dosing system (auger filler) tailored to material parameters such as mesh size, flowability, and sugar content, ensuring precise and efficient filling.

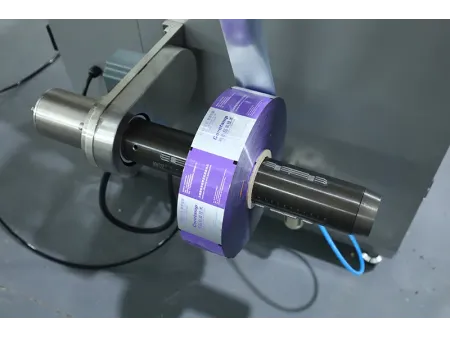

With a maximum film width of 240mm, it produces powder bags ranging from 50-140mm in width and 50-180mm in length. The adjustable dosing system and rotary refill mechanism guarantee exceptional accuracy and speed. Operating at speeds of 20-80 cuts per minute, this equipment is designed for effortless maintenance, allowing all parts in contact with your materials to be quickly disassembled and reassembled. The 45° vertical sealing device ensures superior sealing quality and can be opened from the center for easier maintenance. Optimize your packaging process with this reliable and user-friendly machine. Contact us today to discuss how it can meet your specific needs!

Seal Type: Back Seal, 3 Side Seal, 4 Side Seal

(VFFS Machine for Powdery Products)

| Model | |

| Number of Packaging Lanes | 1 |

| Dosing System | Auger Filler |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1 mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |

(VFFS Machine for Powdery Products)

| Model | |

| Number of Packaging Lanes | 2 |

| Dosing System | Auger Filler |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1 mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |