SPM-DHD Series DTH Hammer with Foot Valve

The SPM-DHD series DTH hammers are optimized for complex geological conditions and designed specifically for geotechnical drilling.

With reliable borehole straightness and stable performance, they are preferred by construction and drilling companies.

Utilizing precise air pressure control technology, the hammers maintain high drilling efficiency while significantly reducing disturbance to surrounding foundations, providing a safer and more environmentally friendly drilling solution for urban infrastructure projects.

The product is available in five sizes (SPM335, SPM340, SPM350, SPM360, and SPM380) and should be selected based on borehole diameter and ground conditions to ensure smooth cuttings removal.

- The front connection of the outer sleeve is prone to wear. A reversible design allows rotation of the sleeve to extend component life.

- Standardized maintenance kits enable most internal components to be professionally repaired and reused. The kit cost is only about 10% of a new hammer, significantly reducing total drilling costs and providing an efficient solution throughout the hammer’s service life.

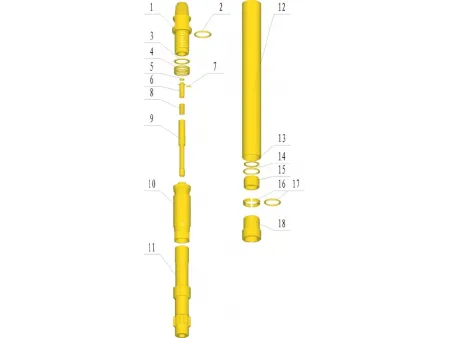

- Top sub

- Top sub with o-ring

- Adjusting pad

- Compression ring

- Valve seal

- Check valve dart

- Feed tube retainer pin

- Check valve dart spring

- Rigid valve finger

- Internal cylinder

- Piston

- Piston case

- Circlip

- Guide sleeve with o-ring

- Guide sleeve

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø90-Ø100 |

| Hammer length, mm | 908 |

| Hammer OD, mm | Ø81 |

| Weight, kg | 21.8 |

| Working pressure, MPa | 0.8-2.1 |

| Air consumption, m³/min | 4.3-14.2 |

| Impact energy, J | 205 |

| Impact frequency, times/min | 950-1500 |

| Connection thread (to bit) | DHD3.5 |

| Connection thread (to drill pipe) | API 2 3/8’ REG Pin |

| Compatible bit shank | SPM335-90/100 |

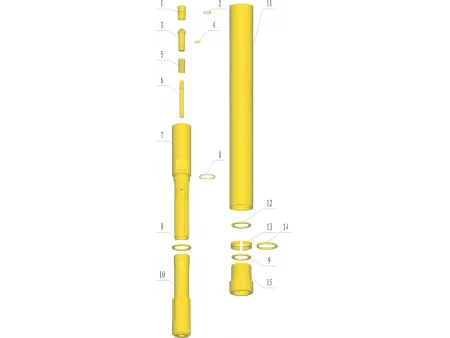

- Choke set

- Choke set with o-ring

- Check valve dart

- Feed tube retainer pin

- Check valve dart spring

- Rigid valve finger

- Inner cylinder

- Inner Cylinder with o-ring

- Steel pad ring

- Piston

- Piston case

- Piston retainer ring

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø105-Ø130 |

| Hammer length, mm | 1052 |

| Hammer OD, mm | Ø92 |

| Weight, kg | 38 |

| Working pressure, MPa | 0.8-2.1 |

| Air consumption, m³/min | 3.5-18 |

| Impact energy, J | 304 |

| Impact frequency, times/min | ≥800 |

| Connection thread (to bit) | DHD340 |

| Connection thread (to drill pipe) | API 2 3/8’ REG Box |

| Compatible bit shank | SPM340-105/110/115/120/130 |

- Top sub

- Top sub with oring

- Adjusting pad

- Compression ring

- Check valve dart

- Feed tube retainer pin

- Check valve dart spring

- Rigid valves

- Rigid valve with oring

- Internal cylinder

- Piston

- Piston case

- Piston retainer ring

- Bit retainer ring

- Bit retainer ring with oring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø130-Ø152 |

| Hammer length, mm | 1387 |

| Hammer OD, mm | Ø117 |

| Weight, kg | 69 |

| Working pressure, MPa | 0.8-2.1 |

| Air consumption, m³/min | 5.7-18 |

| Impact energy, J | 590 |

| Impact frequency, times/min | 810-1470 |

| Connection thread (to bit) | DHD350 |

| Connection thread (to drill pipe) | API 3 1/2’ REG Pin |

| Compatible bit shank | SPM350-130/140/152 |

- Top sub

- Top sub with o-ring

- Steel pad ring

- Compression ring

- Check valve dart

- Feed tube retainer pin

- Check valve dart spring

- Rigid valves

- Rigid valves with o-rings

- Internal cylinder

- Piston

- Piston case

- Guide sleeve

- Adjusting pad

- Circlip

- Bit retainer ring

- Bit retainer ring with o-ring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø152-Ø305 |

| Hammer length, mm | 1450 |

| Hammer OD, mm | Ø136 |

| Weight, kg | 126 |

| Working pressure, MPa | 1.0-2.1 |

| Air consumption, m³/min | 8.5-25 |

| Impact energy, J | 822 |

| Impact frequency, times/min | 820-1475 |

| Connection thread (to bit) | DHD360 |

| Connection thread (to drill pipe) | API 3 1/2' REG Pin |

| Compatible bit shank | SPM360-152/165/178/194/203/216/230/254/305 |

- Top sub

- Top sub with oring

- Top sub with oring

- Steel pad ring

- Compression ring

- Check valve dart

- Check valve dart spring

- Sleeve

- Rigid valves

- Rigid valves with Oring

- Internal cylinder

- Check ring

- Piston

- Piston case

- Rubber ring

- Bit retainer ring

- Bit retainer ring with oring

- Driver sub

Technical Parameters

| Drilling diameter, mm | Ø203-Ø350 |

| Hammer length, mm | 1551 |

| Hammer OD, mm | Ø181 |

| Weight, kg | 208 |

| Working pressure, MPa | 1.0-2.1 |

| Air consumption, m³/min | 12-31 |

| Impact energy, J | 1560 |

| Impact frequency, times/min | 860-1510 |

| Connection thread (to bit) | DHD380 |

| Connection thread (to drill pipe) | API 4 1/2' REG Pin |

| Compatible bit shank | SPM380-203/216/230/245/254/305/311/350 |

Under normal drilling conditions, some external components of DTH hammers are subject to excessive wear due to flushing, while internal components may reach fatigue limits. Wear often occurs at the front connection of the outer sleeve. Many SPM-DHD series hammers feature reversible sleeves to address this. With defined service kits, the hammer can be repaired, and most internal components reused. Use of the maintenance kit extends overall hammer life and substantially reduces total drilling costs, as the kit costs approximately 10% of a new hammer.

SPM-DHD series hammers are designed for installation with drill rods, adapter joints, and other drilling equipment. They must be used with sufficient feed force, tensile force, rotation speed, torque, lubrication air pressure, and air volume. These hammers are suitable for virtually any rock drilling application.