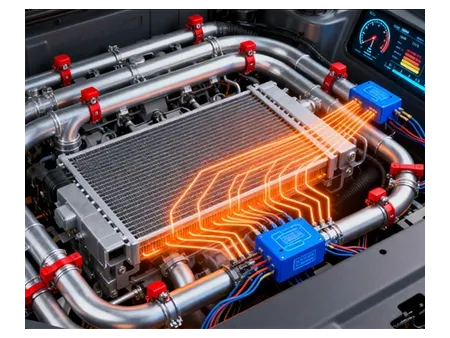

Thermal Management Products

The thermal management system is widely applied in both new energy and conventional vehicles, covering key functions in powertrain, battery, and cooling systems. The system includes intelligent cooling units, radiators, intercoolers, electronic water pumps, and high- and low-voltage electronic fans. These components ensure efficient heat dissipation and stable temperature control for the vehicle under high load and extreme environmental conditions.

As a vehicle manufacturer, what are the main considerations when selecting radiators or cooling systems?

Key factors include compatibility with the vehicle platform, heat dissipation performance, energy efficiency ratio, long-term reliability, compliance with international quality standards (such as IATF 16949), delivery schedule, and after-sales support capability.

How can battery thermal management units ensure compatibility with new energy vehicle designs?

Manufacturers should provide customized design capability, BMS interface compatibility reports, and thermal runaway protection test data, as well as prototype validation and joint testing.

What technical parameters are most important for new energy vehicle manufacturers when selecting electronic water pumps?

Attention is given to high- and low-voltage operating ranges, high-temperature resistance, noise reduction performance, energy efficiency, and long-term stability under continuous heavy-load operation.

What are the key considerations for long-distance transport vehicles when choosing radiator assemblies?

Focus is placed on corrosion resistance during prolonged high-intensity operation, anti-vibration and impact-resistant design, thermal efficiency, maintenance cost, and overall lifecycle cost, including spare parts availability.

What are the core requirements for construction machinery manufacturers when purchasing intercooler assemblies?

Requirements include stable heat dissipation in high-dust, high-humidity, and high-temperature environments, anti-clogging structure, ease of cleaning, and long-term durability. Suppliers are also expected to provide field test data under severe operating conditions.

What do component distributors prioritize when selecting electronic fans?

The focus is on model compatibility, stable inventory, delivery lead time, after-sales warranty policy, and reasonable pricing structure to support rapid maintenance across multiple vehicle brands.

What are the main considerations for performance tuning workshops when sourcing ATS intelligent cooling systems?

Emphasis is placed on heat dissipation efficiency improvement potential, real-time response under high-power output, adjustability, and installation convenience with original vehicle systems.