Biomass Fired Thermal Oil Boiler

Heating capacity : (120-2000)×104kCal/h

Designed pressure: 1.1MPa

Maximum working temperature: 320℃

Fuel type: Biomass Briquette Fuels made from straw, rice husk, palm shell, bark and other waste crops.

The biomass fired thermal oil boiler utilizes thermal oil as a heat carrier, and is an industrial boiler used in low pressure, high temperature environments in order to provide highly efficient heat energy. It is widely used in chemical factories, plastic processing plants, textile processing plants, rubber plants, food processing plants, paper plants and bitumen plants.

| Type | Heating capacity× 104 ( kCal/h ) | System thermal efficiency ( % ) | Designed pressure ( MPa ) | Maximum working temperature ( ℃ ) | Medium circulation flow ( m3/h ) | Main tube diameter( DN ) | Installed capacity( kW ) |

| 120 | 80 | 1.1 | 320 | 100 | 125 | 60 | |

| 160 | 80 | 1.1 | 320 | 160 | 150 | 73 | |

| 200 | 81 | 1.1 | 320 | 160 | 150 | 80 | |

| 250 | 81 | 1.1 | 320 | 200 | 200 | 100 | |

| 300 | 82 | 1.1 | 320 | 200 | 200 | 100 | |

| 350 | 82 | 1.1 | 320 | 260 | 200 | 120 | |

| 400 | 82 | 1.1 | 320 | 260 | 200 | 140 | |

| 500 | 82 | 1.1 | 320 | 300 | 250 | 175 | |

| 600 | 83 | 1.1 | 320 | 340 | 250 | 215 | |

| 700 | 83 | 1.1 | 320 | 400 | 250 | 215 | |

| 800 | 83 | 1.1 | 320 | 520 | 300 | 270 | |

| 900 | 83 | 1.1 | 320 | 600 | 300 | 320 | |

| 100 | 83 | 1.1 | 320 | 600 | 300 | 320 | |

| 1200 | 83 | 1.1 | 320 | 680 | 350 | 380 |

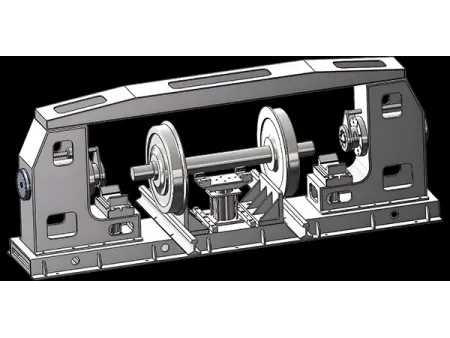

The biomass fuel fired boiler features complex processing links, and utilizes fine processing, which is an important factor in final product quality and safe usage by the customer.

1. Boiler material: seamless steel pipe

2. Welding process: Argon arc welding and radiographic testing

3. Bending shaping: The tube is shaped after the bending process in the pipe bending machine in order to ensure the coil outline dimension accuracy and ensure it meets GB/T17410 standards.

4. Water pressure testing: After shaping, the water pressure test for the tube is carried out before the boiler leaves the factory.

1. Protection function

· Automatically alarm when the liquid level inside the expansion tank is too low.

· Automatically alarm when the thermal oil outlet pressure exceeds rated pressure

· Automatically alarm when the thermal oil temperature is too high

· The system will automatically stop, and sends out an acousto-optic alarm signal if there are any abnormal conditions, such as a shutdown of the circulating pump.

2. Automatic detection function

· The control system can automatically detect pressure and temperature of the heat medium.

· The control system can automatically detect the outlet temperature of the heat medium, and maintain it within the pre-set range.