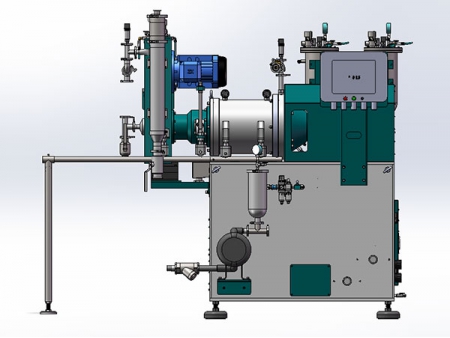

Horizontal Double-Drive Nano Bead Mill, RTSM-10BJD-S

Horizontal double-drive nano bead mill is made based on our customers’ demands and can be used to grind novel nano materials. It is equipped with quality rod pin, of which the configuration is optimized, and the filtering area of the screen has also been largely improved. This is why this nano bead mill is known for its strengthened grinding efficiency and yields, hence meeting the requirements of mass grinding of nano materials.

With regard to technical details, the main motor of this grinder drives, through V-belt, the main shaft rotor to rotate at high speed. At the same time, the shaft rotor drives the grinding medium to move at high speed, thus generating huge impact force, friction force and shear force, which make the material fully ground and mixed.

To deliver the above-mentioned functions, this double-drive bead mill has been made with several advanced techniques. To be specific, the grinding chamber is sealed to avoid the generation of bubbles and the volatilization of additives, hence causing no air pollution. The external static screen on this grinding equipment delivers precise and wear-resistant performance, ensuring ground materials are effectively separated and thus featuring a long service life.

- No screens, thus applicable for under-0.05 mm grinding medium ad suitable for milling materials smaller than 100 nanometers;

- Special separator structure and unique filtering design, ensuring no beads will be left out;

- Slit-type grinding structure, high energy density;

- Reasonable design of material flow channel, high grinding efficiency and uniform particle size;

- Certified mechanical seal, long service life. Solvent can be used as sealing medium for mechanical seal, avoiding pollution even when there is leakage;

- Formula can be easily imported and exported with only pressing the button;

- Sophisticated rotor design, through simulated and actual operation, ensuring excellent grinding efficiency, average-temperature operation and low energy cost.

new energy, lithium battery, silicon carbon nanomaterials, paint, coating, pigment etc.

- Model No. RTSM-10BJD-S

- Volume: 10L

- Main Motor Power: 22kW

- Separating Motor Power: 5.5kW

- Materials of Inner Grinding Chamber Component: Silicone Carbide

- Materials of Outer Grinding Chamber Component: SS304 Stainless Steel

- Grinding Principle: Pin Type

- Materials of Rotor Component: Ceramic

- Max. Line Speed: 15.4m per second

- Screen Component Structure: None

- Operation Method: PLC with Touch Screen

- Mechanical Seal Component Style: Double-end Container Type

- Pneumatic Diaphragm Pump: 1.5-inch Pneumatic Diaphragm Pump