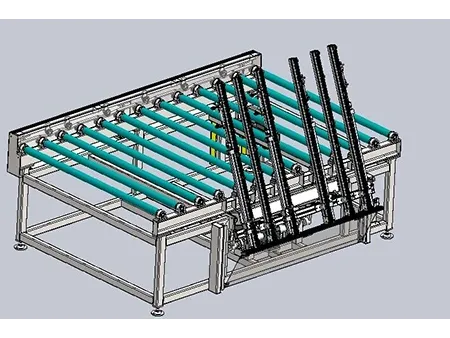

Tilt Unloading Conveyor

Request a Quote

Glass handling table for unloading glass panels at a 70-degree tilt

Tilting unloading conveyors are typically installed at the end of an automated line to assist with manual unloading. By tilting the glass to an ergonomic 70-degree angle, they allow operators to lift and remove panels more easily and safely. Their design helps reduce handling risks while keeping the workflow smooth and efficient.

Features

- The conveyors use a roller transfer system with short-side leading alignment to ensure smooth and accurate glass movement.

- A tiltable support rack is positioned along the vertical direction of the conveyor and can raise the glass to a 70-degree angle, making it easier for the operator to lift the panels.

- The tilting motion is driven by a reduction motor connected to a crank and linkage mechanism, and the movement is regulated by an inverter for smooth and controlled speed adjustment.

- Glass stoppers are mounted on the support beams and operated by pneumatic cylinders. These stoppers hold the glass securely in place during the tilting process to prevent slipping or misalignment.