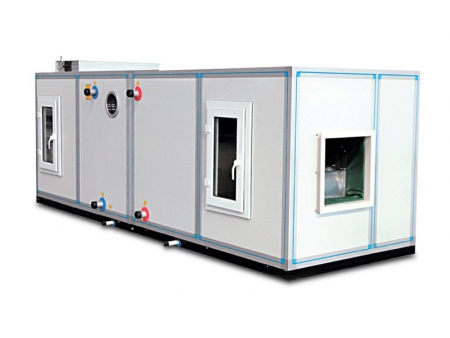

Combined Type Air Handling Unit

Request a Quote

ZK series air heating and cooling units are a multifunctional filter, cooler, heater, humidifier/dehumidifier, heat recovery system and air purification/sterilization system. They are most often used for air conditioning for comfort in offices, hotels, factories, sports facilities, hospitals, conference halls, computer labs, hospitals and a number of other locations. With all of the different function combinations, the air heating and cooling unit can satisfy different customer requirements.

Download

Technical Parameters

| No. | Unit Model - RZK | Module Model - RZK | Nominal air flow m3/h | Inner size | Face Velocity (m/s) | ||||||||||

| W(mm) | H(mm) | 2 | 2.25 | 2.5 | 2.75 | 2.85 | 3 | 3.5 | 4 | 4.5 | 5 | ||||

| 1 | 020 | 0607 | 2000 | 700 | 600 | 1692 | 1880 | 2031 | 2143 | 2256 | 2632 | 3008 | 3384 | 3760 | 4137 |

| 2 | 025 | 0608 | 2500 | 800 | 600 | 2052 | 2280 | 2460 | 2600 | 2736 | 3192 | 3684 | 4105 | 4561 | 5017 |

| 3 | 029 | 0609 | 2900 | 900 | 600 | 2412 | 2680 | 2895 | 3056 | 3216 | 3752 | 4289 | 4825 | 5361 | 5897 |

| 4 | 033 | 0610 | 3300 | 1000 | 600 | 2772 | 3080 | 3327 | 3512 | 3696 | 4313 | 4929 | 5545 | 6161 | 6777 |

| 5 | 038 | 0611 | 3800 | 1100 | 600 | 3132 | 3480 | 3759 | 3968 | 4177 | 4873 | 5569 | 6265 | 6961 | 7657 |

| 6 | 026 | 0707 | 2600 | 700 | 700 | 2176 | 2417 | 2611 | 2756 | 2901 | 3384 | 3868 | 4351 | 4835 | 5318 |

| 7 | 037 | 0709 | 3700 | 900 | 700 | 3102 | 3446 | 3722 | 3929 | 4135 | 4825 | 5514 | 6203 | 6829 | 7852 |

| 8 | 043 | 0710 | 4300 | 1000 | 700 | 3564 | 3960 | 4277 | 4515 | 4753 | 5545 | 6337 | 7129 | 7921 | 8713 |

| 9 | 048 | 0711 | 4800 | 1100 | 700 | 4027 | 4475 | 4833 | 5101 | 5370 | 6265 | 7160 | 8055 | 8950 | 9845 |

| 10 | 041 | 0809 | 4100 | 900 | 800 | 3446 | 3829 | 4135 | 4365 | 4595 | 5361 | 6126 | 6892 | 7658 | 8424 |

| 11 | 048 | 0810 | 4800 | 1000 | 800 | 3960 | 4410 | 4753 | 5017 | 5281 | 6161 | 7041 | 7921 | 8801 | 9581 |

| 12 | 054 | 0811 | 5400 | 1100 | 800 | 4475 | 4972 | 5370 | 5668 | 5966 | 6961 | 7955 | 8950 | 9944 | 10939 |

| 13 | 060 | 0812 | 6000 | 1200 | 800 | 4989 | 5544 | 5987 | 6320 | 6652 | 7761 | 8870 | 9978 | 11087 | 12196 |

| 14 | 066 | 0813 | 6600 | 1300 | 800 | 5504 | 6115 | 6604 | 6971 | 7338 | 8561 | 9784 | 11007 | 12230 | 13453 |

| 15 | 072 | 0814 | 7200 | 1400 | 800 | 6018 | 6687 | 7221 | 7623 | 8024 | 9361 | 10698 | 12036 | 13373 | 14710 |

| 16 | 057 | 0910 | 5700 | 1000 | 900 | 4753 | 5281 | 5703 | 6020 | 6337 | 7393 | 8449 | 9505 | 10561 | 11617 |

| 17 | 072 | 0912 | 7200 | 1200 | 900 | 5987 | 6652 | 7184 | 7584 | 7983 | 9313 | 10644 | 11974 | 13305 | 14635 |

| 18 | 081 | 1012 | 8100 | 1200 | 1000 | 6735 | 7484 | 8082 | 8532 | 8981 | 10477 | 11974 | 13471 | 14968 | 16464 |

| 19 | 089 | 1013 | 8900 | 1300 | 1000 | 7430 | 8255 | 8916 | 9411 | 9960 | 11557 | 13209 | 14860 | 16511 | 18162 |

| 20 | 097 | 1014 | 9700 | 1400 | 1000 | 8124 | 9027 | 9749 | 10291 | 10832 | 12638 | 14443 | 16248 | 18054 | 19859 |

| 21 | 11 | 1015 | 10600 | 1500 | 1000 | 8819 | 9798 | 10582 | 11170 | 11758 | 13718 | 15677 | 17637 | 19597 | 21556 |

| 22 | 11 | 1016 | 11400 | 1600 | 100 | 9513 | 10570 | 11415 | 12050 | 12684 | 14798 | 16912 | 19026 | 21140 | 23254 |

| 23 | 090 | 1112 | 9000 | 1200 | 1100 | 7484 | 8315 | 8981 | 9479 | 9978 | 11641 | 13305 | 14968 | 16631 | 18294 |

| 24 | 12 | 1115 | 11800 | 1500 | 1100 | 9798 | 10887 | 11758 | 12411 | 13064 | 15242 | 17419 | 19597 | 21774 | 23952 |

| No. | Unit Model (RZK) | Nominal air flow (m3/h) | 2Rows | 4Rows | 6Rows | 8Rows | ||||||||

| Sensible Cooling (KW) | Total Cooling (KW) | Water Flow (m3/h) | Sensible Cooling (KW) | Total Cooling (KW) | Water Flow (m3/h) | Sensible Cooling (KW) | Total Cooling (KW) | Water Flow (m3/h) | Sensible Cooling (KW) | Total Cooling (KW) | Water Flow (m3/h) | |||

| 1 | 0607 | 2000 | 5 | 7 | 1.2 | 9 | 12 | 2.1 | 10 | 14 | 2.5 | 13 | 17 | 2.8 |

| 2 | 0608 | 2500 | 6 | 8 | 1.4 | 10 | 14 | 2.4 | 12 | 17 | 2.9 | 15 | 19 | 3.3 |

| 3 | 0609 | 2900 | 6 | 9 | 1.5 | 11 | 16 | 2.8 | 14 | 19 | 3.3 | 17 | 22 | 3.8 |

| 4 | 0610 | 3300 | 8 | 11 | 1.9 | 14 | 20 | 3.4 | 17 | 24 | 4.1 | 21 | 28 | 4.7 |

| 5 | 0611 | 3800 | 9 | 13 | 2.2 | 16 | 23 | 4.0 | 20 | 28 | 4.7 | 24 | 32 | 5.5 |

| 6 | 0709 | 3700 | 8 | 12 | 2.1 | 15 | 21 | 3.6 | 18 | 25 | 4.3 | 22 | 29 | 5.0 |

| 7 | 0710 | 4300 | 9 | 13 | 2.2 | 17 | 24 | 4.4 | 21 | 29 | 5.0 | 25 | 33 | 5.7 |

| 8 | 0809 | 4100 | 10 | 14 | 2.4 | 19 | 26 | 4.5 | 22 | 31 | 5.4 | 28 | 36 | 6.2 |

| 9 | 0810 | 4800 | 11 | 16 | 2.8 | 21 | 29 | 5.0 | 25 | 35 | 6.0 | 31 | 40 | 6.9 |

| 10 | 0811 | 5400 | 13 | 18 | 3.1 | 23 | 32 | 5.5 | 27 | 38 | 6.6 | 34 | 44 | 7.6 |

| 11 | 0812 | 6000 | 14 | 19 | 3.3 | 25 | 35 | 6.0 | 30 | 42 | 7.2 | 37 | 48 | 8.3 |

| 12 | 0813 | 6600 | 16 | 22 | 3.8 | 29 | 40 | 6.9 | 34 | 48 | 8.3 | 42 | 55 | 9.5 |

| 13 | 0814 | 7200 | 17 | 24 | 4.1 | 31 | 44 | 7.6 | 38 | 53 | 9.1 | 47 | 61 | 10.4 |

| 14 | 0910 | 5700 | 13 | 18 | 3.1 | 24 | 33 | 5.7 | 28 | 40 | 6.8 | 35 | 46 | 7.8 |

| 15 | 0912 | 7200 | 16 | 23 | 4.0 | 29 | 41 | 7.1 | 35 | 49 | 8.5 | 44 | 57 | 9.7 |

| 16 | 1012 | 8100 | 18 | 26 | 4.5 | 34 | 47 | 8.1 | 40 | 56 | 9.7 | 50 | 65 | 11.2 |

| 17 | 1013 | 8900 | 21 | 30 | 5.2 | 39 | 54 | 9.3 | 46 | 65 | 11.1 | 57 | 75 | 12.8 |

| 18 | 1014 | 9700 | 24 | 33 | 5.7 | 43 | 60 | 10.3 | 51 | 72 | 12.4 | 64 | 83 | 14.2 |

| 19 | 1015 | 10600 | 26 | 36 | 6.2 | 46 | 65 | 11.2 | 56 | 78 | 13.4 | 69 | 90 | 15.4 |

| 20 | 1115 | 11800 | 28 | 39 | 6.7 | 51 | 71 | 12.2 | 61 | 85 | 14.7 | 75 | 98 | 16.9 |

| 21 | 1116 | 12700 | 30 | 42 | 7.2 | 54 | 76 | 13.1 | 65 | 91 | 15.7 | 81 | 105 | 18.0 |

| 22 | 1117 | 13600 | 32 | 45 | 7.7 | 58 | 81 | 13.9 | 69 | 97 | 16.7 | 86 | 112 | 19.2 |

| 23 | 1217 | 15000 | 34 | 48 | 8.3 | 62 | 87 | 15.0 | 75 | 104 | 18.0 | 92 | 120 | 20.7 |

| 24 | 1218 | 15800 | 36 | 51 | 8.8 | 66 | 92 | 15.8 | 79 | 110 | 19.0 | 98 | 127 | 21.8 |

| 25 | 1317 | 16100 | 38 | 53 | 9.1 | 69 | 97 | 16.7 | 83 | 116 | 20.0 | 103 | 134 | 23.0 |

| 26 | 1318 | 17200 | 40 | 57 | 9.8 | 73 | 103 | 17.7 | 89 | 123 | 21.2 | 110 | 142 | 24.4 |

| 27 | 1319 | 18300 | 43 | 60 | 10.3 | 77 | 109 | 18.7 | 94 | 130 | 22.4 | 116 | 150 | 25.8 |

| 28 | 1418 | 19100 | 45 | 63 | 10.8 | 81 | 114 | 19.6 | 98 | 137 | 23.5 | 121 | 157 | 27.1 |

| 29 | 1420 | 21600 | 49 | 69 | 11.9 | 89 | 125 | 21.5 | 107 | 150 | 25.8 | 133 | 173 | 29.7 |

| 30 | 1519 | 21900 | 51 | 72 | 12.4 | 94 | 131 | 22.5 | 112 | 157 | 27.0 | 139 | 181 | 31.1 |

| Remarks: | Cooling conditions : inlet air DB 35℃,WB28℃;inlet and outlet water temperature 7℃/12℃。 | |||||||||||||

| No. | Unit Model (RZK) | Nominal air flow (m3/h) | 2Rows | 4Rows | 6Rows | 8Rows | ||||

| Total Cooling (KW) | Water Flow (m3/h) | Total Cooling (KW) | Water Flow (m3/h) | Total Cooling (KW) | Water Flow (m3/h) | Total Cooling (KW) | Water Flow (m3/h) | |||

| 1 | 0607 | 2000 | 13 | 1.1 | 21 | 1.8 | 27 | 2.3 | 34 | 13 |

| 2 | 0608 | 2500 | 16 | 1.4 | 26 | 2.2 | 34 | 2.9 | 42 | 16 |

| 3 | 0609 | 2900 | 19 | 1.6 | 30 | 2.6 | 40 | 3.4 | 50 | 19 |

| 4 | 0610 | 3300 | 23 | 2.0 | 37 | 3.2 | 48 | 4.2 | 61 | 23 |

| 5 | 0611 | 3800 | 27 | 2.3 | 43 | 3.7 | 57 | 4.9 | 72 | 27 |

| 6 | 0709 | 3700 | 25 | 2.2 | 40 | 3.4 | 53 | 4.5 | 66 | 25 |

| 7 | 0710 | 4300 | 29 | 2.5 | 46 | 4.0 | 61 | 5.2 | 77 | 29 |

| 8 | 0809 | 4100 | 31 | 2.7 | 50 | 4.3 | 65 | 5.6 | 82 | 31 |

| 9 | 0810 | 4800 | 34 | 2.9 | 54 | 4.7 | 71 | 6.1 | 90 | 34 |

| 10 | 0811 | 5400 | 38 | 3.3 | 61 | 5.2 | 80 | 6.9 | 101 | 38 |

| 11 | 0812 | 6000 | 41 | 3.5 | 66 | 5.6 | 86 | 7.4 | 109 | 41 |

| 12 | 0813 | 6600 | 46 | 4.0 | 74 | 6.3 | 97 | 8.3 | 122 | 46 |

| 13 | 0814 | 7200 | 51 | 4.4 | 82 | 7.0 | 107 | 9.2 | 135 | 51 |

| 14 | 0910 | 5700 | 39 | 3.4 | 62 | 5.4 | 82 | 7.0 | 103 | 39 |

| 15 | 0912 | 7200 | 47 | 4.0 | 75 | 6.5 | 99 | 8.5 | 125 | 47 |

| 16 | 1012 | 8100 | 54 | 4.6 | 86 | 7.4 | 113 | 9.8 | 143 | 54 |

| 17 | 1013 | 8900 | 62 | 5.3 | 99 | 8.5 | 130 | 11.2 | 164 | 62 |

| 18 | 1014 | 9700 | 69 | 5.9 | 110 | 9.5 | 145 | 12.5 | 183 | 69 |

| 19 | 1015 | 10600 | 76 | 6.5 | 122 | 10.5 | 160 | 13.7 | 201 | 76 |

| 20 | 1115 | 11800 | 84 | 7.2 | 134 | 11.6 | 176 | 15.2 | 223 | 84 |

| 21 | 1116 | 12700 | 91 | 7.8 | 146 | 12.5 | 191 | 16.4 | 241 | 91 |

| 22 | 1117 | 13600 | 100 | 8.6 | 160 | 13.8 | 210 | 18.1 | 265 | 100 |

| 23 | 1217 | 15000 | 107 | 9.2 | 171 | 14.7 | 225 | 19.3 | 284 | 107 |

| 24 | 1218 | 15800 | 114 | 9.8 | 182 | 15.7 | 239 | 20.6 | 302 | 114 |

| 25 | 1317 | 16100 | 121 | 10.4 | 194 | 16.6 | 254 | 21.9 | 321 | 121 |

| 26 | 1318 | 17200 | 129 | 11.1 | 205 | 17.6 | 270 | 23.2 | 340 | 129 |

| 27 | 1319 | 18300 | 136 | 11.7 | 216 | 18.6 | 286 | 24.6 | 359 | 136 |

| 28 | 1418 | 19100 | 142 | 12.2 | 227 | 19.5 | 298 | 25.6 | 376 | 142 |

| 29 | 1420 | 21600 | 148 | 12.7 | 237 | 20.4 | 311 | 26.7 | 392 | 148 |

| 30 | 1519 | 21900 | 154 | 13.2 | 246 | 21.2 | 323 | 27.8 | 408 | 154 |

Features

- Materials: steel profiles, colored steel panels or galvanized steel plates.

- Excellent air impermeability: an elastic strip seal is used to seal the gap between the panel, frame and other adapting pieces, in order to ensure air leak levels are low, thus meeting customer and industrial requirements.

- Anti-condensation: A rational design and configuration prevents cold bridges and condensation during operation.

- Many configuration options: Several optimized options for heat exchange coils and parts meet the requirements of different cases.

- Convenient installation: Quick, onsite installation is the norm. The unit is equipped with an access door and lock technology with automatic tensioning functions in order to easily carry out maintenance on inner parts.

- Automatic control system: the unit can be equipped with a micro-computerized controller, fan starter and frequency converter, in order to achieve different intelligent running modes and accurately control each parameter of the air conditioning system.

Functional Section

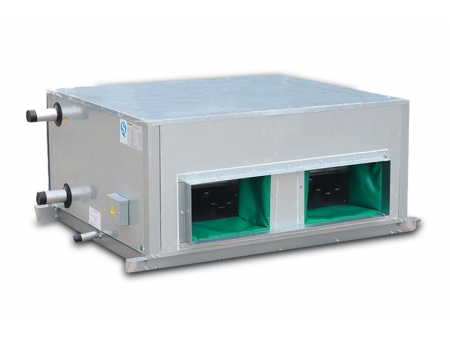

- Return air section: This section is located at the inlet side of the unit. It is equipped with an axial flow fan, designed to ensure the return air flow regardless of any resistance within the air flue.

- Mixed air section: This section is equipped with an exhaust valve and outside air damper respectively. Two sections are separated by a mixer selector valve. This section is designed to regulate the air flow.

- Section with medium efficiency filter bag: It works for the primary air supply filter, and is located in the back of the mixed air section. The filter material is comprised of non-woven fabrics.

- Spray Section: This section is located behind the filter bag, and is used for humidifying, cooling and dust removal of the air in the units. The spray room is composed of a water supply system, spray system, water fender and water pool.

- Surface cooling section: This section cools the air when the temperature of the supplied air is too high. This section is made of a copper tube.

- Air supply section: This section includes the air intake fan and air exhaust fan.

- Other functional sections: water retaining section, evaporation section, high-efficiency self-cleaning cartridge filter section and combustion section.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos