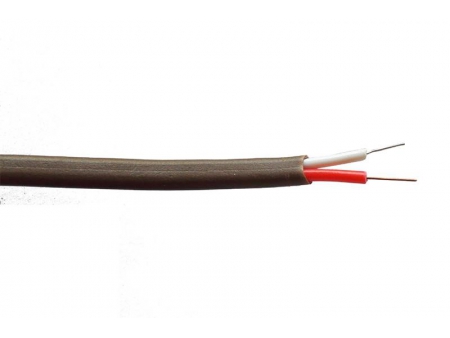

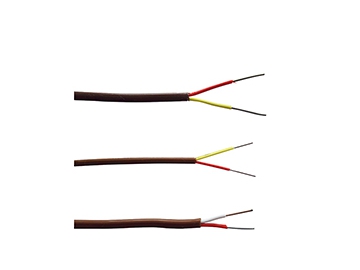

Nuclear Power Plant Compensating Cable, Class 1E

Category K3, Low Smoke, Halogen Free, Flame Retardant

Standard Class 1E nuclear power plant compensating cable is manufactured according to Q/320411AVX019 (RCC-E,IEEE 323,IEEE 383)standard.

Properties 1. Rated voltage: 300/500V.

2. The permitted long-term working temperature of conductor: 90℃.

3. The permitted bending radius of the compensating cable: No less than 8 times of the overall diameter of the cable.

4. The Min. environmental temperature: -15℃. (Ambient temperature can be due to customer demand)

5. Min. laying temperature of the cable is 0℃. The cable should be pre-heated if it is below the Min. laying temperature

6. Normal service life: at least 40 years.

7. Combustibility

7.1 The cable can pass the test according to GB/T 18380.34( IEC 60332-3-23).

7.2 For cross-linked polyolefin insulated cable, the insulated core can pass the test according to GB/T 18380.12 (IEC60332-1).

8. The cable can pass the test according to GB/T 17651(IEC 61034).

9. Insulation and sheath material of the cable should be tested according to GB/T 17650(IEC 60754-2), with pH no less than 4.3, and conductivity should be less than 10ms/mm.

10. Electrical properties:

10.1 It can withstand AC 2500V/5min high voltage test between the insulated conductors.

10.2 It can withstand AC 1500V/5min high voltage test between the insulated conductor and shield.

10.3 Insulation resistance at 20℃ is shown in table 4.

10.4 Thermo- emf, permissible tolerance are shown in table 5.

10.5 Reciprocal resistance at 20℃ is shown in table 6.

Application Compensating cable is suitable for linking thermocouples and recording instruments. These particular cables are designed for use in nuclear power plants and have been appraised as a technological achievement by the China National Nuclear Corporation (CNNC).

Explanation of Symbols

| Item | Symbol | Explanation |

| Type of compensating cable | See table 2 | See table 2 |

| Symbol of fire-resistance | NH | Fire-resistance |

| Insulation | YJ | XLPE insulated |

| YJ1 | XLPO insulated | |

| Individual screen | (Omitted) | No shield |

| P1 | Tinned copper braided individual screen | |

| P2 | Cu/plastic tape wrapped individual screen | |

| P3 | Al/plastic tape wrapped individual screen | |

| Overall screen | (Omitted) | No shield |

| C1 | Tinned copper braided overall screen | |

| C2 | Cu/plastic tape wrapped overall screen | |

| C3 | Al/plastic tape wrapped overall screen | |

| Bedding sheath | E | Thermoplastic low-smoke, halogen-free and flame-retardant Polyolefin sheathed |

| Armor | 2 | Steel tape armored |

| 3 | Steel wire armored | |

| Outer sheath | E | Thermoplastic low-smoke, halogen-free and flame-retardant Polyolefin sheathed |

| Flame-retardant grade | A | Category A bunched flame-retardant |

| B | Category B bunched flame-retardant | |

| C | Category C bunched flame-retardant | |

| Halogen-free property | 3 | Low-smoke, halogen-free |

| Size | Number of groups× number of cores in each group× nominal sectional area(mm 2 ), there into: Number of groups: 1~40. Number of cores in each group: 2. Nominal sectional area (mm2): 0.35~2.5. | |

| Note: You can select all kinds of combinations to meet your requirements. Usually, the conductor type is Class 2. It needs to be specified if Class 5 required. | ||

For more details, please download the PDF!