Forgings for Thermal Power

TongYu is now one of the major manufacturers of large castings and forgings in China. We provide all kinds of free forgings used for thermal power, hydroelectric, and .

Turbine rotors and generator rotors are required to work under a high speed of 3000-3600r/min, and high/medium pressure rotors for steam turbine have to bear a temperature of 400-560℃. So the materials for high/medium pressure rotors of steam turbine must own the properties of high temperature resistance, good plasticity and toughness, high creep strength, and low ductile - brittle transition temperature. Requirements for the materials for low-pressure rotor of steam turbine and generator rotor are the same. Besides, generator rotors have to possess good magnetic permeability.

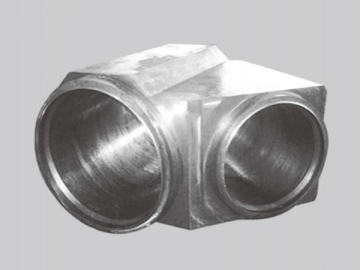

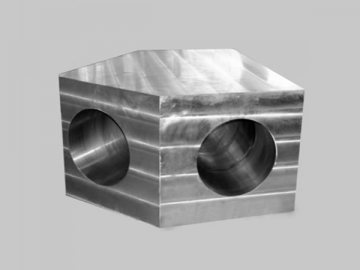

P91 ultra-high pressure forged 3-way pipe connector

P91 ultra-high pressure forged 3-way pipe connector

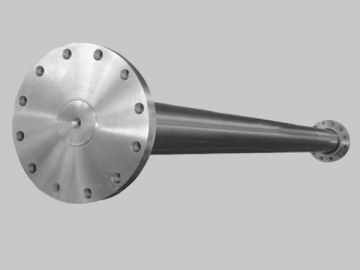

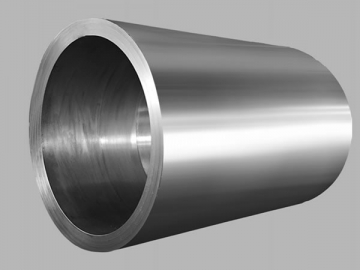

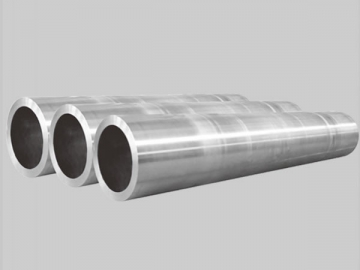

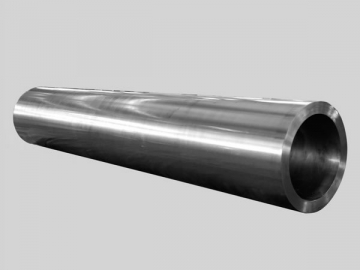

DN500mm-1168mm supercritical boiler tube for power station

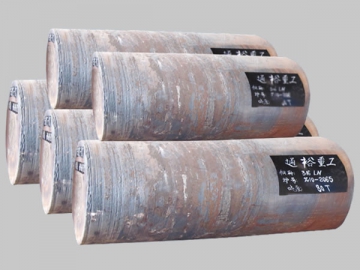

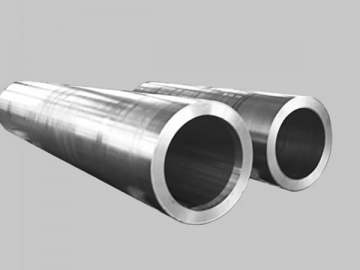

Ultra-high pressure forged large-diameter seamless steel pipes

Ultra-high pressure forged large-diameter seamless steel pipes

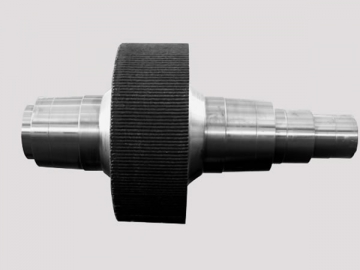

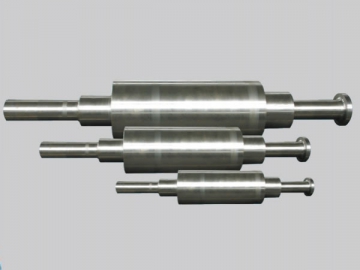

Generator rotors for large steam turbine

Forged turbine rotor shaft

Forged turbine rotor shaft

TongYu has established strict inspection system for each of the production steps from smelting, forging, heat treatment, flaw detection, to mechanical processing. The turbine rotors and generator rotors we have produced are in conformity with the national and European standards, such as JB/T1265, JB/T7022, JB/T7025, JB/T7026, and SEW555.

Materials

34CrMo1A, 34CrNi1Mo, 25Cr2Ni4MoV, 30Cr2Ni4MoV, 28CrNiMoV, 30Cr2MoV, 30Cr1Mo1V, etc.

Manufacturing Process

Smelting – Forging – Heat Treatment – Roughing – Quenching and Tempering – Semi Finishing – Stress-Relief Annealing – Machining – Packaging

Quality Control

1. In the smelting process, strict control is needed for some harmful elements, gas, and non-metallic impurities, like P, S, Pb, Sn, As, Sb, Bi, H, O, and N, apart from the prescribed chemical components.

2. For producing large rotors or rotors for special uses, double vacuum smelting or electroslag remelting techniques are necessary to guarantee the raw materials' high purity, uniform components, and low gas content.

3. Strict forging technique is required to meet the nondestructive testing needs. After being forged, the blanks will undergo normalizing and diffusion annealing process to realize refined grains and low hydrogen content.

4. The quenching and tempering treatment is conducted on materials to achieve high comprehensive mechanical properties, large grain size and good microstructure.

5. CNC equipment is adopted for high processing accuracy.

Why Choose TongYu Rotors

1. The rotors we have produced for turbines and generators are characterized by high strength, great plasticity and toughness, and low ductile - brittle transition temperature

2. High purity and uniform chemical components

3. Large grain size and uniform structure

4. Little defected parts in nondestructive testing