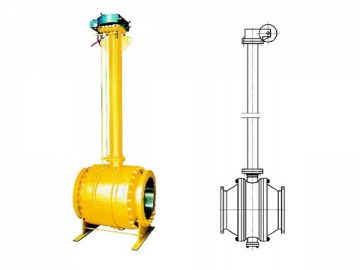

Fully Welded Ball Valve (for Buried Applications)

Fully welded buried type ball valve is used for underground applications in construction, so it must be highly resistant to corrosion. The ball valve we provide is equipped with fire-resistant structure, anti-static device, self-locking device, stem fixing structure, and high-performance sealing material. The rated pressure and temperature of the underground ball valve is determined according to the ANSIB16.34 standards. Flange dimension is compliant with the ANSIB16.5 standards.

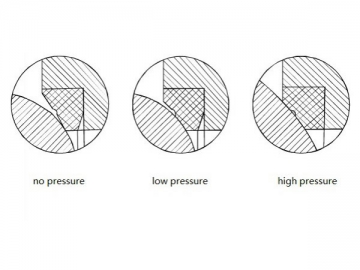

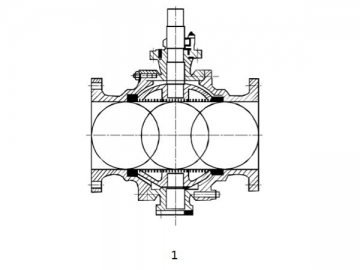

1. Sealing Structure of Seat

The floating ball valve employs V-shaped seal ring to reduce the friction between the ball and the seal ring, as well as to reduce the operating torque. When there is a low medium pressure, the contact area between the seal ring and ball is small and the sealing result is reliably guaranteed; when the medium pressure enlarges, the contact area gets larger accordingly, and the ring won't get damaged under large pressure.

According to the pressure, fixed ball valve is able to choose different sealing manners.

A: input end sealing; B: output end sealing; C: double ends sealing

2. Auxiliary Sealing Structure

We can equip the valve seat and the sealing part of the stem with grease valve, which will protect the sealing system when the ball valve is leaking.

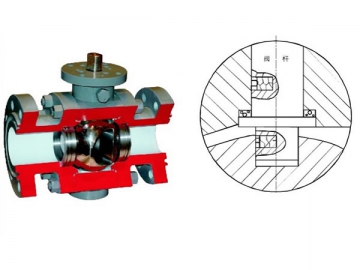

3. Inverted Sealing Structure

The valve stem employs an inverted sealing structure equipped with sealing gasket. The sealing effect gets better as the pressure enlarges. When there is an abnormal pressure increase, the stem won't get impacted. A V-shaped structure is adopted for the fillers to effectively transfer the medium pressure and the locking force of the outer bonnet into the sealing force of the stem.

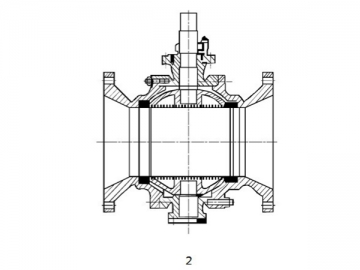

4. Full Bore and Reduced Bore Structure

Our ball valves are available in full bore ball valve and reduced bore ball valve. For full bore type, the bore diameter is consistent with the inner diameter of pipes, allowing for little flow resistance and easy cleaning. Ball valve with reduced bore shows much less flow resistance comparing with shutoff valve with the same bore diameter, and the weight is 30% less than that of ball valve with the same diameter.

-

1. Full bore ball valve

1. Full bore ball valve -

2. Reduced bore ball valve

2. Reduced bore ball valve

5. Anti-Static Structure

Anti-static structure is optional for our ball valve. It is realized by setting a conductive spring between the ball, the stem, and the valve body. Then the static electricity generated in the valve opening and closing process will flow into the ground through the metal spring. In this way, the risk of flammable media will be effectively eliminated.

6. Refractory Structure

The ball valve is designed into a refractory structure so all of the sealing parts will help to prevent the medium from spreading when there is a fire.

7. Security Lock

At the opening and closing location of the valve we have set lock hole for security consideration.

8. Automatic Pressure Relief Structure

When there is an abnormal pressure increase due to the rise of temperature, the medium in the cavity will push the seat backward to ensure the valve's safety.

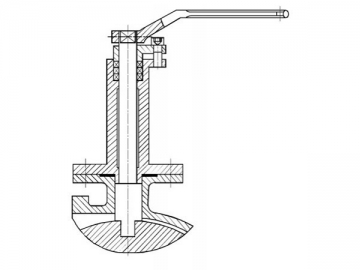

9. Low Temperature Structure

The valve adopts extended-stem design in case that the sealing effect of the stem may fail when working in low-temperature condition. An automatic pressure relief structure is available.

10. Buried Type Extended Stem Design

The extended valve stem makes the valve applicable in underground applications.

Body: A182 316, A350 LF2, A105

Bonnet: A350 LF2, A182 316, A105

Injection valve: A276-316, 1045

O-shaped seal ring: fluorine rubber

Support ring of seat: A350 LF2 electroless nickel plating, A182-F316, A105

Seal ring: PPL

Spring: INCONEL X 750

Ball: electroless nickel plating A350 LF2, A182-F316, A105 electroless nickel plating

Sliding bearings: 304 PTFE, 316 PTFE

Electrostatic spring: A276-316

Stem: A182 F6a, A182-F316

Gaskets: PTFE 304, PTFE 316

Filler: graphite

Screws: A193 7M, A193-B7M, A193-B8, A193-B7

Drain valve: 1045, A182-F316

Lining: electroless nickel plating A350 LF2, A182-F316, A105

Lining pin: A182-F316, 1045, A350 LF2 electroless nickel plating

Upper sleeve: A350 LF2 electroless nickel plating, A105, A182-F316

Locating pins: A276-316, 1045

Coupling plate: A182-F316, A105, A350 LF2

Seat: A276-316, 1025