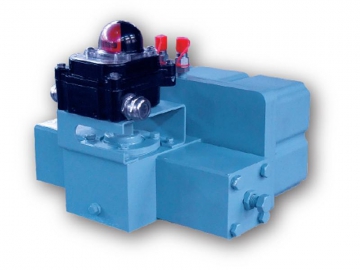

Double Acting Hydraulic Cylinder (HSG)

Request a Quote

Hydraulic Components, Hydraulic Systems Components

Double Acting Hydraulic Cylinder(HSG), a vital part in hydraulic system, is independently researched and developed by ourselves. This kind of hydraulic cylinder possesses a number of attractive features, including compact structure, light weight, easy to disassemble and maintain, flexible connecting method and stable working performance.

Double acting hydraulic cylinder has found an extensive application in engineering machinery, mining machinery, transportation machinery and many other fields.

Product Parameters

- Rated pressure: 160bar (No fatigue under rated pressure)

- Hydraulic oil: Mineral hydraulic oil (Or others)

- Standard sealing temperature range: -20℃~ 80℃

- Connecting: Cylinder head with screw threads or clamps, cylinder cover with welding technique

- Inner diameter of cylinder: 40mm -320mm

- Diameter of piston rod: 22mm-220mm

- Stroke: Customized

- Buffer device: Either end or both ends

Major Components

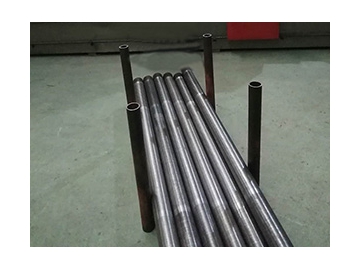

- Cylinder Tube

A smooth cylinder tube can effectively protect the inner sealed parts. Thus, each tube produced by Hoyo must undergo strict inspection and examination, allowing for a low roughness degree and friction coefficient. - Piston rod

Piston rod is made of high strength carbon alloy steel, and features a precision ground surface which is chrome-plated and polished to a 0.2 μm finish, significantly extending the service life of the gland seal. What's more, the piston rod surface is induction hardened before chrome-plating, achieving a surface hardness of higher than HRC54. The induction hardened piston rod boasts excellent impact resistance. Under a rated working pressure, all piston and piston rod are fatigue free. - Cylinder head & cylinder cap fixing plate

First, cylinder head & cylinder cap is connected to a thick steel flange with screws. Then, the flange is fixed on the both ends of the cylinder tube by screw thread. - Cylinder tube

Thick walled cylinder is ground and polished to a very high surface finish, so that the friction coefficient is small, which maximizes the seal life. - Cylinder head & cylinder cap end

Cylinder head and cylinder cap is manufactured with high quality steel. The cylinder head is installed in the cylinder, providing added strength to the cylinder. The joint of the cylinder head, cylinder cap and cylinder tube is designed with an O-ring supported by an anti-extrusion ring, giving excellent sealing effect. - Cushioning

Designed with cushioning, the noise and shock loading can be greatly reduced, resulting in a faster cycle times and higher working efficiency. The cylinder speed can also gradually decrease due to the cushions at the cylinder head and cylinder cap. The cylinder head end cushion features a self-centering design. What's more, the polished cap end spear is an integral part of the piston rod. - Floating cushion bushes and sleeves

The excellent cushioning is achieved by the use of a floating cushion sleeve at the cylinder head end and a floating cushion bush at the cylinder cap end. - Piston rod guide sleeve

Piston rod seal includes a heavy load polymer support ring resisting side loading is installed in the steel guide sleeve assembly. The large support ring area can be separated from the rod seal, so that the supporting stress achieves to the minimum, therefore maximizing the support ring life. The piston rod guide sleeve assembly is connected to with the cylinder head using screw thread or bolt depending on the bore. The support ring and rod seal is easy to replace after removing the guide sleeve. - Piston rod and piston seal

A variety of piston rods and piston seals can be chosen to suit different working conditions. In addition, MMA-Y series cylinder can be sealed in accordance with customer requirements. - Bleed valve

Bleed valve can be installed in the cylinder either one end or both ends, which is retained in the cylinder head or cylinder cap, thus in case the bleed valve is inadvertently removed. The position of bleed valve is depending on the position of oil port, and therefore should be specified when ordering. - Guide sleeve-Oil drain port on the guide sleeve

The oil adhering to the piston rod is easy to accumulate between the sealing ring and dust ring on the guide sleeve assembly when operating the hydraulic cylinders with a long stroke, constant pressure and 2:1 ratio of extending and retracting speed. The accumulated oil can be drained with added an oil drain port on the guide sleeve assembly. The drained oil is allowed to re-enter the oil tank, and the height of the tank should be less than that of the cylinder.

- Finished cylinder tube

Piston rod

Piston rod- Assembly machine of seal rings

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos