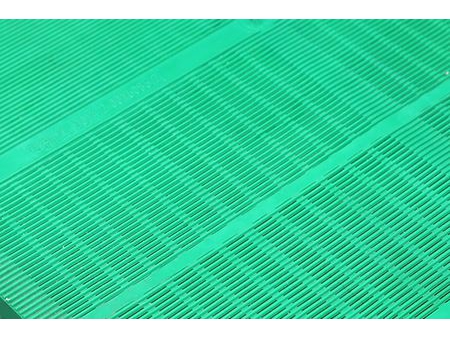

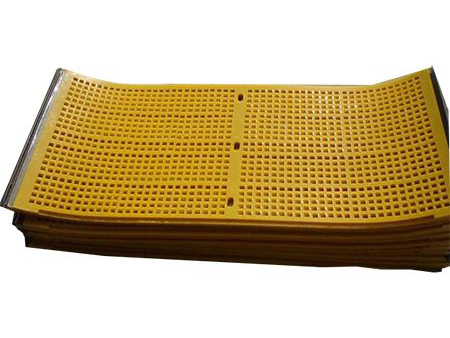

Polyurethane Screen

Request a Quote

DUNPAI manufactures its polyurethane screens with organic polymer materials, meaning that the polyurethane screens are resistant to abrasion, oil corrosion, aging and impact. Based on polyurethane, our screens feature great load capacity and their specifications can be customized based on your demands.

Features

- Thermosetting and thermoplasticity;

- Apertures: 0.3 mm – 100 mm;

- Prepare raw materials and put pre-polymers into an oven for heating;

- Manufacture preliminary metal screens, conduct abrasive blasting and adhesive coating;

- Clean molds and propel release agents on them;

- Place the metal screens in the molds and pour the pre-polymers on the screens.

- Carry out the curing and drying of the screens

| Square Mesh | Rectangle Mesh | ||||||

| Aperture Width | Plate Thickness | Tensioning Thickness | Compression Thickness | Aperture | Plate Thickness | Tensioning Thickness | Compression Thickness |

| 2.50 | 7 | 25 | 30 | 0,20x11,00 | 8 | 30 | 30 |

| 2.80 | 7 | 25 | 30 | 0,30x16,00 | 7 | 30 | 30 |

| 3.20 | 7 | 25 | 30 | 0,40x11,00 | 8 | 30 | 30 |

| 4.00 | 7 | 25 | 30 | 0,50x16,00 | 7 | 30 | 30 |

| 4.50 | 8 | 25 | 30 | 0,60x11,00 | 8 | 30 | 30 |

| 5.00 | 9 | 25 | 30 | 0,80x16,00 | 7 | 30 | 30 |

| 5.50 | 8 | 25 | 30 | 1,00x11,00 | 8 | 25 | 30 |

| 6.20 | 9 | 25 | 30 | 1,20x11,00 | 8 | 27 | 30 |

| 6.50 | 9 | 25 | 30 | 1,50x11,00 | 8 | 25 | 30 |

| 7.30 | 9 | 25 | 30 | 1,50x20,00 | 8 | 25 | 30 |

| 7.50 | 9 | 25 | 30 | 1,50x25,00 | 8 | 25 | 30 |

| 8.00 | 9 | 25 | 30 | 2,00x20,00 | 8 | 25 | 30 |

| 9.50 | 10 | 25 | 30 | 2,50x20,00 | 8 | 25 | 30 |

| 10.00 | 11 | 25 | 30 | 3,00x20,00 | 8 | 25 | 30 |

| 11.50 | 12 | 25 | 30 | 4,00x20,00 | 12 | 25 | 30 |

| 12.50 | 13 | 25 | 30 | 4,50x20,00 | 8 | 35 | 30 |

| 13.00 | 13 | 25 | 30 | ||||

| 14.00 | 13 | 25 | 30 | ||||

| 15.00 | 15 | 25 | 30 | ||||

| 16.50 | 16 | 25 | 30 | ||||

| 17.50 | 15 | 25 | 30 | ||||

| 18.50 | 15 | 25 | 30 | ||||

| 20.00 | 18 | 30 | 30 | ||||

| 22.00 | 18 | 30 | 30 | ||||

| 23.00 | 18 | 30 | 30 | ||||

| 24.00 | 24 | 30 | 30 | ||||

| 25.00 | 24 | 30 | 30 | ||||

| 25.90 | 22 | 30 | 30 | ||||

| 27.00 | 24 | 30 | 30 | ||||

| 28.00 | 21 | 30 | 30 | ||||

| 30.00 | 24 | 30 | 30 | ||||

| 32.00 | 21 | 30 | 30 | ||||

| 35.00 | 28 | 35 | 35 | ||||

| 37.00 | 28 | 35 | 35 | ||||

| 40.00 | 27 | 35 | 35 | ||||

| 42.50 | 28 | 35 | 35 | ||||

| 45.00 | 28 | 35 | 35 | ||||

| 50.00 | 37 | 40 | 40* | ||||

| 55.00 | 40 | 40 | 40* | ||||

| 60.00 | 40 | 40 | 40* | ||||

| 65.00 | 40 | 40 | 40* | ||||

| 70.00 | 40 | 40 | 40* | ||||

| 75.00 | 40 | 40 | 40* | ||||

| 80.00 | 45 | 45 | 45* | ||||

| 85.00 | 45 | 45 | 45* | ||||

| 90.00 | 45 | 45 | 45* | ||||

| 95.00 | 45 | 45 | 45* | ||||

| 100.00 | 35 | 35 | 35 | ||||

| 120.00 | 40 | 40 | 45* | ||||

Polyurethane dewatering screen panels are widely used in various dewatering, screening, classification, and recovery scenarios due to their excellent wear resistance, corrosion resistance, high elasticity, and self-cleaning capabilities.

- Mining and mineral processing:

- Tailings dewatering: Removing excess water from tailings during tailings management for subsequent dry stacking or landfill.

- Ore classification: Used for wet screening and classification of ores.

- Coal slurry recovery: Recovering fine-grained coal slurry from coal washing wastewater.

- Aggregate industry:

- Manufactured sand dewatering: Removing excess water during sand making to improve the quality of finished sand.

- Fine sand recovery: Recovering fine sand from slurry wastewater to reduce resource waste.

- Aggregate classification: Used for particle size classification of aggregates.

- Chemical and pharmaceutical industries:

- Chemical particle dewatering: Used for dewatering wet chemical particles, such as potassium nitrate and calcium chloride.

- Pharmaceutical particle screening: Performing particle classification and dewatering during drug production.

- Metallurgical industry:

- Steel plants: Classification and dewatering of ore powder and steel slag.

- Coke screening: Screening fine powder from coke.

- Metal powder processing: Screening and classifying metal powders for further processing.

- Water treatment industry:

- Sludge dewatering: Used for sludge dewatering in municipal sewage treatment plants and industrial wastewater treatment.

- Seawater desalination: Separating particulate matter during the saltwater filtration stage.

- Drinking water treatment: Removing suspended particles from water.

- Building materials industry:

- Cement plants: Separating cement particles to ensure the quality of finished products.

- Ceramic plants: Dewatering and classifying ceramic raw materials.

- Concrete production: Recovering fine sand and water from waste concrete.

Hook Style