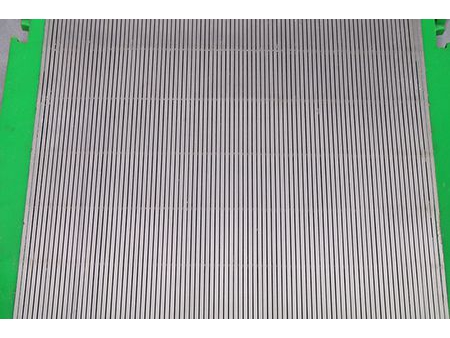

Modular Screen Panel

DUNPAI’s modular screen panels, metal and non-metal types, can be used and changed efficiently and conveniently. When certain screens are broken, they can be changed individually, which avoids the change of whole panels. Our screen panel lineup includes several products—modular metal screen panel, polyurethane screen panel, modular polyurethane screen panel, high-efficiency dewatering panel, with each boasting different features. In addition, DUNPAI is also able to manufacture diverse special screening products to be installed in different screening machines.

The standard sizes of our modular screen panels are 305mm*305mm and 305mm*610mm, other sizes can be customized according to customer's individual needs.

- Applications: screening, dewatering, washing;

- Industries served: coal, mining, food, pharmaceuticals;

- Materials and mesh specifications are customizable;

- Resistant to abrasion;

- Light weight, small noise, high screening effectiveness, cost-effectiveness, environmental friendliness;

- Feature excellent dewatering capacity;

- Applicable for separating water from mud on the surface of tunnel boring machine;

- Applicable for filtering water from mud during the tunneling;

- Industries served: mining, sand and gravel industry;

- Resistant to abrasion;

- Light weight, small noise, high screening effectiveness;

- Meshes are relatively large;

- Applicable for classifying raw coal and separating ores;

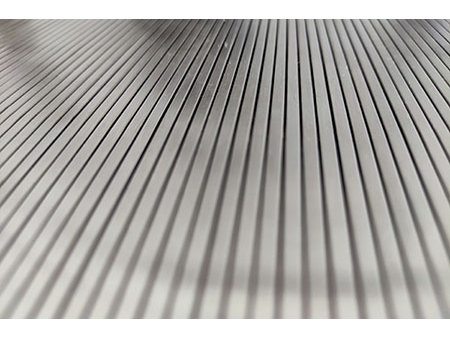

Wedge wire screens (modular screen panel) are specially designed metal screens made of V-shaped or wedge-shaped wires welded to support rods. Due to their unique structure, wedge wire screens exhibit excellent performance in various scenarios and material handling applications.

- Water treatment and filtration: Used for primary filtration and solid-liquid separation, such as removing large suspended solids and particles.

- Mining and mineral processing:

- Coal screening: Used in coal washing plants to separate coal fines and water.

- Metal ore screening: Processing ores like gold, iron, and copper for particle size classification.

- Tailings management: Recovering valuable minerals and reducing waste discharge.

- Food processing:

- Beverage production: Filtering impurities from fruit juices, beer, and other beverages.

- Food production: Used for syrup filtration, flour sifting, and oil separation.

- Aquatic processing: Removing debris and impurities during fish processing.

- Oil and chemical:

- Refineries: Separating liquid and solid impurities such as sediment and suspended solids.

- Chemical production: Filtering chemicals and catalysts.

- Well operations: Used as downhole screen pipes to prevent sand and gravel from entering the wellbore.

- Pharmaceutical industry:

- Liquid drug filtration: Removing particles and precipitates from liquid medications.

- Powder classification: Used for sifting pharmaceutical powders to ensure uniform particle size.

- Solid-liquid separation: Separating solids and liquids in pharmaceutical production.

- Paper and textile industries:

- Pulp filtration: Removing plastics, fibers, and other impurities from waste paper.

- Textile wastewater treatment: Filtering fibers and particles from textile industrial wastewater.

(Regular size: 305*305, 305*610; Other sizes are customizable)

| Model(S/N) | A(mm) | B(mm) | b(mm) | |

| 1 | 90 | 50 | ≥4 | |

| 2 | 80 | 40 | ≥4 | |

| 3 | 40 | 40 | ≥4 |

Other sizes are customizable