Automatic Disposable Medical Mask Machine

Request a Quote

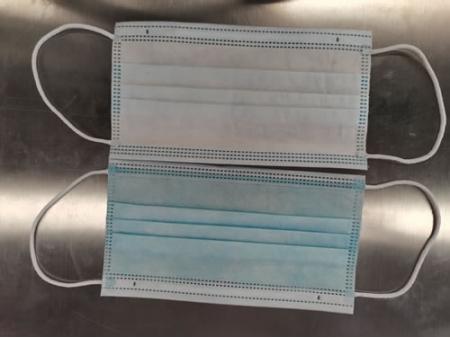

The disposable medical mask machine features all automatic production processes described as below:

- The roll of fabric gets unrolled and driven by rollers, then gets automatically folded and wrapped;

- The nose clip gets pulled and unwound, cut to a fixed length and then inserted into the edging fabric;

- The two sides of the fabric are welded and sealed by ultrasonic, then the fabric gets cut and formed by the cutter;

- Finally the blank mask is sent to the ear-loop welding stations, ear-loops get welded onto the mask, and the mask is finally finished. Finished masks are transported and collected automatically.

Features

- Simple operation, stable performance and high efficiency.

- Compact size, space-saving.

- Aluminum alloy frame, sturdy, elegant and rust-proof.

- Mitsubishi PLC is applied, available for custom programming and modification.

Parameters

Model: TYGK-21

Capacity: 100-120pcs/min

Weight: 1600kg

Dimension: 6400*3200*1680mm(L*W*H)

Power: 11kW

Machine material: aluminum alloy

Control: PLC

Raw material inspection: photoelectric inspection