Liner Hanger

Liner Hanger

1. DYX-AF Series Liner Hanger (withpacker)

DYX-AFliner hanger with packer can block up the overlapping annulus effectively toprevent eicherblase caused by gas or fluid migrationbetween the casing and stratum. After well cementation, the packer drains outredundant mud without affecting the stratum below.

Working Principle

Whenthe liner reaches the predetermined position, it will hang, reverse, cement andbump the well. Then it raises the driller and makes the block stretch out toset on the up end of tie-back sleeve, the driller under which shears the pins.The roller will expand under the action of external force to seal the uppercasing and tie-back sleeve.

Features

1. The line hanger is designed withself-locking device to ensure convenient, permanent packing.

2. The pressure required for setting is30-50t.

3. The line hanger has isolation capacityof about 30MPa.

4. It can resist temperature of

Specifications

A: Φ244.5× Φ

B: Φ177.8 × Φ

Parameters

| Specifications (mm) | A | B |

| Packer pressure (t) | 30 | 30 |

| Rated load (t) | 120 | |

| Seal capacity (MPa) | 25 | 25 |

| Shearing pressure for hanger (MPa) | 7-8 | 7-8 |

| Shearing pressure for setting (MPa) | 12 | 12 |

| Max. OD of body (mm) | 215 | 152 |

| Inner diameter of body (mm) | 155 | 108.6 |

| Length of tieback tank (mm) | 2800 | 2800 |

| Inner diameter of tieback tank (mm) | 187 | 133 |

| Casing wall thickness (mmA) | 10.0 11.05 11.99 | 9.19 10.36 |

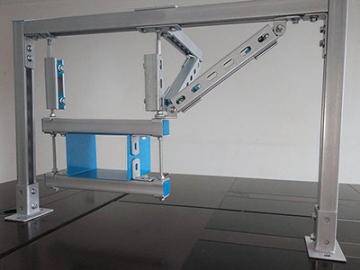

2. DYX-A Hydraulic Liner Hanger

TheDYX-A liner hanger is designed with single cone. It is hydraulically set byapplying pressure through the run-in string. A setting ball is circulated ordropped to a ball seat built into the landing collar. Applied pressure acts onthe internal piston and moves slips up the cone to the set position.

Features

1. Hydrauliccontrol

2. TheDYX-A liner hanger can be used to work with SQ ball setter, to suit applicationto horizontal and highly deviated wells.

3. Theseal components are made of NBR or fluorine rubber to ensure resistance to hightemperature of 120℃ or even above.

4. Mainparts, the hydraulic cylinder, e.g. are made by use of high-strength structuralalloy steel to offer excellent mechanical properties.

Specifications

A:Φ244.5 × Φ

B: Φ177.8 × Φ

Parameters

| Specifications (mm) | A | B |

| Rated load (t) | 120 | 50 |

| Sealing capacity (MPa) | 25 | 25 |

| Shearing pressure of pins (MPa) | 7-8 | 7-8 |

| Casing wall thickness (mm) | 10.03 11.05 11.99 | 9.19 10.36 11.51 |

| Casing weight (Kg/m) | 59.52 64.73 69.94 | 38.69 43.15 47.62 |

| Max. O.D. of body (mm) | 215 | 152 |

| Body I.D. (mm) | 155 | 108 |

Thanksfor visiting website of DezhouRundong Company. We are a professional Chinese linerhanger manufacturer, providing mud pump, valve, hose, cementing tool, and otherproducts. With over 40 years of production experience of petroleum machinery,we are able to provide high quality products for worldwide customers. In orderto better serve our customers, we offer customized equipment and accessories aswell as “three guarantees”, that is, repair, replacement and refund of ourproducts. If you have any interest in our products, please click the relatedpages or contact us directly. We at Rundong are happyto assist you.