Planetary Reducer

A precision planetary reducer is a high-accuracy, high-efficiency reduction device, with its core transmission structure comprising planetary gears, a sun gear, and an internal ring gear. Its primary functions are to reduce rotational speed, increase torque, and decrease the rotational inertia ratio of the load motor. These reducers are commonly installed on stepping motors and servo motors.

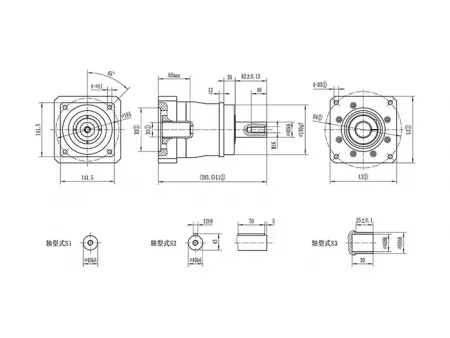

The planetary reducer represents an extension of Kean's gear technology into complete drive systems. Kean proudly introduces the KS140/180 planetary reducer, engineered with high-quality alloy steel (HRC57-60) and a helical gear design. The KS140/180 delivers high torque, low backlash, and smooth operation, all within a compact, easy-to-maintain unit. Leveraging Kean's 23 years of high-precision gear machining capabilities and experience, along with over 30 patents and advanced Gleason and ZEISS equipment, Kean ensures outstanding performance. Please refer to the parameter tables and dimension drawings below for detailed specifications!

| Ratios | i | / | 3 | 4 | 5 | 7 | 8 | 10 | |

| Nominal output torque | T2N | Nm | 200 | 330 | 330 | 320 | 310 | 330 | |

| Emergency stop torque ② | T2Not | Nm | 1250 | 1320 | 1320 | 1320 | 1250 | 1250 | |

| Max. acceleration torque ③ | T2B | Nm | 460 | 790 | 790 | 790 | 640 | 640 | |

| Nominal input speed | n1N | rpm | 2100 | 2100 | 2100 | 2600 | 2600 | 2600 | |

| Max. input speed | nIMAX | rpm | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 | |

| Max. backlash | / | arcmin | ≤3 | ||||||

| Torsional stiffness | / | Nm/arcmin | 50 | ||||||

| Max. axial force ④ | F2AMax | N | 9700 | ||||||

| Max. radial force ④ | F2AMax | N | 9750 | ||||||

| Efficiency | η | % | 97 | ||||||

| Life time | / | h | >20000 | ||||||

| Weight | / | kg | 17.5 | ||||||

| Noise emission | / | dB | ≤65 | ||||||

| Operation temperature | / | ℃ | 90 | ||||||

| Ambient temperature | / | ℃ | -15 to 40 | ||||||

| Lubrication | / | / | Lifetime lubrication | ||||||

| Rotation direction | / | / | Same rotation direction for input and output axes | ||||||

| Degree of gearbox protection | / | / | IP65 | ||||||

| Mass moment of inertia (input) | J1 | 38 | kgcm² | 15 | 12.15 | 11.00 | 10.20 | 9.50 | 9.50 |

- ①: Dimensions depend on the motor; please contact us for details. D1 standard sizes: Ø38 (for KS140).

- ②: Life cycle rating: ≤1000 times.

- ③: Per hour rating: ≤1000 times.

- ④: At an output speed of 100rpm, applied at the center position of the output shaft.

| Ratios | i | / | 3 | 4 | 5 | 7 | 8 | 10 |

| Nominal output torque | T2N | Nm | 510 | 920 | 920 | 825 | 825 | 860 |

| Emergency stop torque ② | T2Not | Nm | 2750 | 2750 | 2750 | 2750 | 2750 | 2750 |

| Max. acceleration torque ③ | T2B | Nm | 1160 | 1450 | 1450 | 1450 | 1165 | 1165 |

| Nominal input speed | nIN | rpm | 1500 | 1500 | 1500 | 2300 | 2300 | 2300 |

| Max. input speed | nIMax | rpm | 4500 | 4500 | 4500 | 4500 | 4500 | 4500 |

| Max. backlash | / | arcmin | ≤3 | |||||

| Torsional stiffness | / | Nm/arcmin | 165 | |||||

| Max. axial force ④ | F2AMax | N | 13950 | |||||

| Max. radial force ④ | F2QMax | N | 15200 | |||||

| Efficiency | η | % | 97 | |||||

| Life time | / | h | >20000 | |||||

| Weight | / | Kg | 34 | |||||

| Noise emission | / | dB | ≤65 | |||||

| Operation temperature | / | ℃ | 90 | |||||

| Ambient temperature | / | ℃ | -15 to 40 | |||||

| Lubrication | / | / | Lifetime lubrication | |||||

| Rotation direction | / | / | Same rotation direction for input and output axes | |||||

| Degree of gearbox protection | / | / | IP65 | |||||

| Mass moment of inertia (input) | J1 48 | Kg/cm² | 58.30 | 41.30 | 35.50 | 29.80 | 29.70 | 26.60 |

| J1 55 | 66.00 | 50.00 | 44.10 | 38.70 | 38.70 | 35.60 | ||

- ①: Dimensions depend on the motor; please contact us for details. D1 standard sizes: Ø48/Ø55 (for KS180).

- ②: Life cycle rating: ≤1000 times.

- ③: Per hour rating: ≤1000 times.

- ④: At an output speed of 100rpm, applied at the center position of the output shaft.