Three Zone Thermal Shock Chamber

Request a Quote

The three zone thermal shock chamber is used to determine how long materials can withstand constant and sharp temperature changes. This equipment is designed to test the extent of both chemical and physical damage resulting from expansion caused by heat, and contractions caused by cold temperatures. Testable materials include metal, plastic, rubber and more.

The three zone thermal shock chamber has no basket, as moving samples is unnecessary. This equipment will expose the materials to sharp temperature changes by blowing hot or cold air into the test chambers.

Features

- Our compressor, expansion valve and oil separator are all sourced from famous international brands.

- Large observation window: The glass features a vacuum coating that prevents frosting, thus making any defrosting processes unnecessary, as well as allowing customers to clearly observe samples at all times.

- Separated humidifying pipes and control circuits: humidifying pipes are separated from power, controller and circuit boards. This separation prevents the humidifying pipes from becoming damaged by heated wires, and makes any repairs easy.

- We use nitrogen as the shielding gas when welding copper pipes, and use a rotary vane pump with two rotors to maintain a vacuum state inside, ensuring the refrigeration system remains clean.

- The tray installed in the bottom of compressor can make water condense and collect, then drain via the drainage pipes.

- The touch-screen displays current function, rest time and cycles, and operation time.

- Customers can pre-set a time, and after turning on the switch, the machine will automatically operate at that time.

- KOMEG's thermal shock chamber can be connected to the internet using professional software, allowing users to remotely control the equipment, collect testing data and control other equipment on a production line.

- Our thermal shock chamber will automatically defrost, and customers can then continue to carry out the testing process, or retest the materials.

- Our products are customized according to customer requirements, ensuring our equipment is both efficient and energy saving. We will adjust and inspect each machine before delivery in order to ensure the customer receives nothing but the best product.

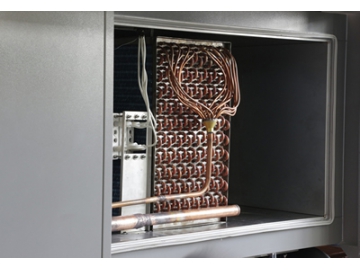

- Condenser

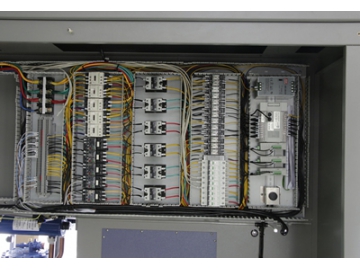

Switchboard

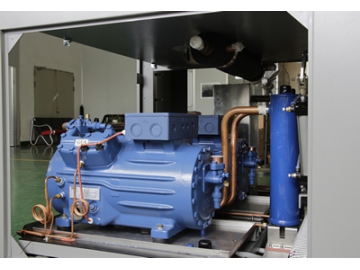

Switchboard  Compressor

Compressor  Cable port

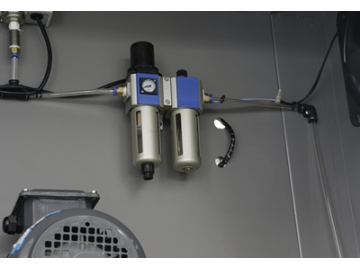

Cable port  Pressure gauge

Pressure gauge

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos