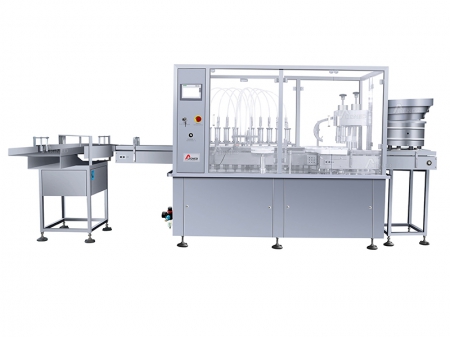

Automatic Liquid Filling and Capping Machine

Request a Quote

ALFC Series

Our automatic liquid filling and capping production machine has been designed specifically for the pharmaceutical, food, and health supplement industries. It is suitable for a variety of liquid products, including syrups, oral solutions, lotions, and topical medicines. It maximizes production output within a compact space and fully complies with the latest GMP standards.

The automatic filling and capping machine is highly versatile, capable of handling bottles of various shapes and sizes. This makes it an ideal choice for production environments that require high throughput and precision.

Technical Specifications

| Model | | | | |

| Filling Capacity Options | 100-100ml/100-500ml/500-1000ml | 100-100ml/100-500ml/500-1000ml | 100-100ml/100-500ml/500-1000ml | 100-100ml/100-500ml/500-1000ml |

| Filling Heads | 4 heads | 8 heads | 10 heads | 12 heads |

| Capping Heads | 1 head | 2 heads | 2 heads | 2 heads |

| Filling Speed | 30-50bpm (depending on the filling volume) | 80-100bpm (depending on the filling volume) | 80-100bpm (depending on the filling volume) | 80-100bpm (depending on the filling volume) |

| Filling Accuracy | ±1% | ±1% | ±1% | ±1% |

| Supply Voltage | 380V/220V 50Hz | 380V/220V 50Hz | 380V/220V 50Hz | 380V/220V 50Hz |

| Power | 3.0kW | 4.0kW | 4.0kW | 4.0kW |

| Weight | Approxi. 800 kg | Approxi. 980 kg | Approxi. 980 kg | Approxi. 980 kg |

| Dimension | 2400×1250×1750mm | 3200×1350×1750mm | 3200×1350×1750mm | 3200×1350×1750mm |

Features

- Supports filling volumes from 10ml to 1000ml, catering to both small bottles and large-capacity production. The servo motor control ensures high precision with no dripping, guaranteeing product consistency and minimizing waste.

- This filling machine can be configurable with 4 to 12 filling heads, offering flexibility to adapt production capacity. The compact design minimizes floor space requirements, making it ideal for facilities with limited space.

- It is equipped with an imported plc control system and an intuitive touchscreen interface for easy operation. It also features automatic diagnostics and alarm functions, ensuring high efficiency and long-term stability.

- Suitable for round, flat, and irregularly shaped bottles, meeting diverse packaging requirements in pharmaceuticals, food, and health supplements.

- Fully adheres to GMP, FDA, and other international regulations. Key components are made from 316L stainless steel, ensuring cleanliness and hygiene in all product-contact areas.

- Features automatic bottle detection, positioning, and a “no bottle, no fill” mechanism to reduce manual intervention. The capping system includes adjustable torque for secure, damage-free sealing, further enhancing product quality and safety.