Rod Mill

Rod Mill

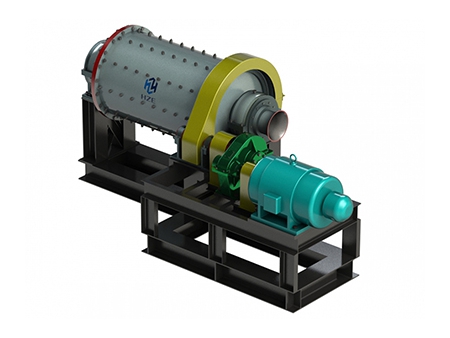

Rod mill is special equipment for building sand, which is suitable for grinding the ores and other materials of different hardness. In particular, it can be used to adjust the fineness modulus on the artificial sand process. During production, the stone enters from both ends of this machine and then comes out from the middle. In use of the rotation of the shell, the rod can repeatedly impact and smash the rock and then produce the required sand.

Our rod mill can provide wide applications in metal and non metal mines, water conservation, glass, building materials, quartz sand, as well as coal, water and slurry preparation etc.

Main Technical Parameters

Model | Specification | Effective volume, m3 | Rotational speed, r/min | Max. load of ball, t | Driving motor | Weight, kg | |

Model | Power, KW | ||||||

MBY0918 | Φ900×1800 | 0.9 | 35.4 | 2.5 | Y | 22 | 5633 |

MBY0924 | Φ900×2400 | 1.2 | 35.4 | 3.55 | Y | 30 | 6877 |

MBY1224 | Φ1200×2400 | 2.2 | 27.75 | 4.8 | Y | 45 | 13700 |

MBY1530 | Φ1500×3000 | 5 | 30.9 | 8.6 | JR117-8 | 80 | 17784 |

MBY2130 | Φ2100×3000 | 9 | 21.3 | 27 | JR137-8 | 210 | 50000 |

MBY2136 | Φ2100×3600 | 12.3 | 21.3 | 27 | JR138-8 | 245 | 57400 |

MBY2736 | Φ2700×3600 | 20 | 21.3 | 51 | TDQ215/29-32 | 400 | 69700 |

Main Characteristics

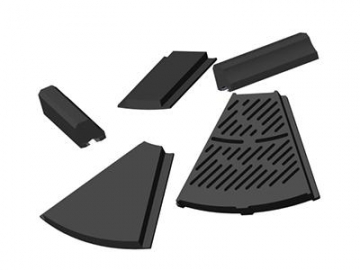

1. This rod mill features innovative structure, stable operation, high yield, low noise, cubic shape, large bulk density, durability and no wear. Thanks to the sealing method, it can provide a more comfortable and healthier production environment in prevention of dust pollution.

2. By utilizing rolling bearing instead of sliding bearing, our product can significantly reduce the energy by 10 to 20 percent. Under the same power condition, it can increase the production capacity by 10 to 20 percent.

3. In use of dry oil type lubricating grease rather than thin oil type, this large grinding mill does not need to be equipped with expensive lubrication station of high or low pressure.

4. If the rod mill possesses the diameter of above

4. Due to the distinct feeding granularity and discharging granularity as well as the different types of materials, the production capacity of our rod mill can be extremely different. Thus, the production capacity shown in the table is just for reference. The dry process has poor material liquidity, the production capacity of which is only 40 percent to 70 percent of that of the wet process.

-------------------------------------------------------------------------------

Rod Mill是研磨介质为钢棒的grinding mill。它的干法生产由于物料流动性很差,生产能力仅为湿法的40%~70%,因此棒磨机一般都适用于湿法细碎、粗磨各种硬度的矿石及其它物料,特别适用于人工造砂过程中调节细度模数。棒磨机是生产建筑用砂的专用设备,将各种岩石、砂石制成各种粒度的建筑用砂,粒度均匀,耐压强度及纯度高。

我公司生产的棒磨机采用滚动轴承支承代替轴瓦滑动轴承支承及棒式滚筒密封制砂等技术,具有运转平稳、节能、产量高、破碎比大、噪音小、耐磨损、滚筒棒式密封、无粉尘污染、可整形产品等特点。另外我公司的产品采用油润滑脂代替价格高昂的稀油润滑站,可降低生产成本。由于棒磨物料种类、给料粒度、排料粒度不同,生产能力差别很大,技术性能参数表中所示生产能力仅供参考。我公司生产的棒磨机可根据用户需要选配。