Case Studies

SiC Heat Exchanger

SiC Heat Exchanger  SiC heat exchangers ready for shipment

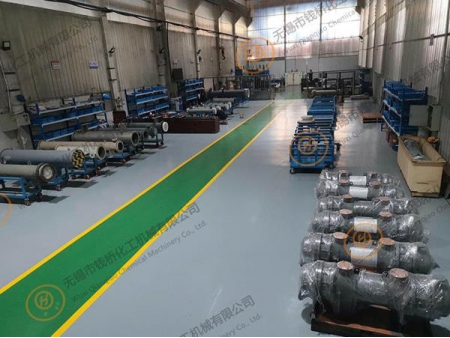

SiC heat exchangers ready for shipment

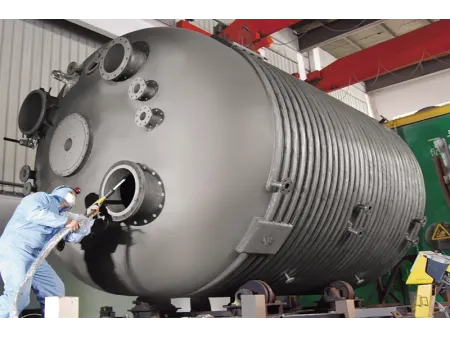

Qianqiao Chemical Machinery is a leading manufacturer of SiC heat exchangers that cater to a wide range of industrial applications. These heat exchangers are constructed with high-quality, corrosion-resistant SiC tube sheets and are the perfect solution for heating, cooling, and condensing chemically corrosive fluids in harsh environments.

In particular, SiC heat exchangers are well-suited for handling thermal fluids such as bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid, alkalis, halogenated compounds, salt solutions, and organic compounds.

Qianqiao Chemical Machinery’s WFE series of glass-lined wiped film evaporators are engineered specifically for industries that require highly corrosive media evaporation, processing of materials to prevent the separation of metal ions, treatment of high viscosity materials, heat-sensitive material processing, and evaporation of high-boiling point substances. These evaporators are designed and manufactured with non-metallic materials such as lined glass or PTFE in areas where they come into direct contact with liquid or gas material, ensuring optimal performance and durability even when exposed to harsh chemicals.

- Glass lined piping can be used for produce glass-lined pipe fittings including ranging from Model DN25 to Model DN2000, and related glass-lined accessories. For models below DN250, the length is generally less than 3000mm while for DN300 and above, the length can reach up to 4000mm.

- Glass lined piping is uniformly manufactured using a cold-spray process, which requires workers to repeatedly grind, refine and dry out the raw materials and enamel powder for the glass lining. The resulting glass-lined piping produced by this technique have a higher burn-through ratio, uniform porcelain layer thickness, and a tight bond between the glass layer and metal substrate which minimizes the occurrence of defects such as bubbles or chipping on the porcelain surface.

- Qianqiao Chemical Machinery adheres to national standards and more stringent European and DIN standards for glass-lining process.

- Qianqiao Chemical Machinery has a long-term cooperative relationship with well-known European enamel factories, ensuring the purchase of high-quality enamel powder that produces glass-lined components that can withstand harsh working conditions such as those involving chloroacetic acid.