Capability

MRU has been dedicated to the manufacturing of cylinder kits since 2003. We have rich industry experience, allowing us to design and produce reliable and high-quality cylinder. In our factory we have introduced high precision equipment, such as CNC machines, honing machines, and more to maximize our capabilities. A good quality control system has also been established to help us better meet the demands of our customers.

We offer standard cylinder for various products across different brands. The thickness of the ceramic layers and the size of cylinder bores of our standard cylinder can be modified to meet your special requirements. If our standard cylinder don’t meet your application needs, we can produce cylinders customized according to your submitted drawings or samples.

The cylinders operate with minimal friction, lower weight, improved heat transfer, and they feature an extended working lifetime. Their heat conductivity coefficient is 42% better than bimetallic cylinders. All raw materials will be tested to confirm they are qualified by our standards before manufacturing can begin.

Nikasil-coating based on high silicon aluminium alloy which contributes to the inner bore of cylinder to have extra wear-resisting performance, special lubricating performance and excellent heat dissipation.

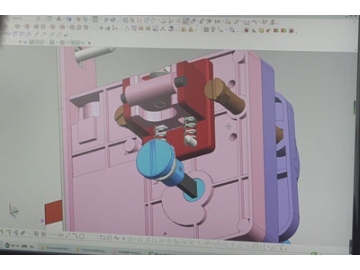

Advanced equipment enables us to manufacture high quality cylinder. We use equipment supplied by well-known brands that maximize our precision and efficiency.

- CNC machines from Brother Industries Ltd in Japan ensures the roundness, cylindricity, straightness, and verticality of our cylinder. These machining centers can also be applied to fully automated production lines by attaching robotic arms.

Our cold chamber die-casting machine ensures the optimal appearance and size of our cylinder according to the design. By attaching robotic arms, its capacity can reach up to 1000 pieces per day.

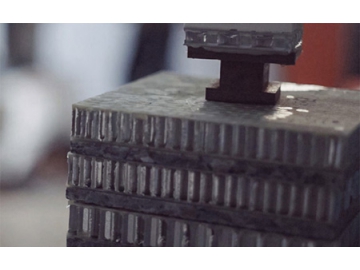

Our cold chamber die-casting machine ensures the optimal appearance and size of our cylinder according to the design. By attaching robotic arms, its capacity can reach up to 1000 pieces per day. Vertical honing machine ensures the cylindricity, roughness, and crosshatch angles of cylinder.

Vertical honing machine ensures the cylindricity, roughness, and crosshatch angles of cylinder.

We carry out strict quality control over each procedure of cylinder manufacturing from the raw material testing, process quality control, to finished product inspecting. The thickness, hardness, and roughness of cylinder walls are all inspected.

Optical Emission Spectrometer

Optical Emission Spectrometer Coordinate Measuring Machine

Coordinate Measuring Machine

Hardness Tester

Hardness Tester High Precision Electronic Measuring Instrument

High Precision Electronic Measuring Instrument Metallographic Analyzer

Metallographic Analyzer Tensile Testing Machine

Tensile Testing Machine