Mesocarbon Microbeads Drying System

Industrial Drying Solutions

We provide industrial drying solutions for mesocarbon microbeads (MCMBs) used as lithium-ion battery anode materials

Drying Conditions and Considerations for Mesocarbon Microbeads (MCMB)

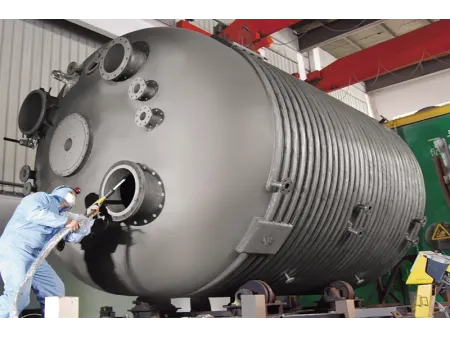

Drying mesocarbon microbeads presents unique challenges as they contain wash oil with a high boiling point, which must be recovered during the drying process. As the oil evaporates, it can cause MCMB to agglomerate, making uniform drying more difficult. MCMB also requires a clean working environment, extended residence time inside the dryer, and careful handling, as it is prone to ignition when exposed to air. For many years, there were no suitable systems that could meet all these requirements effectively.

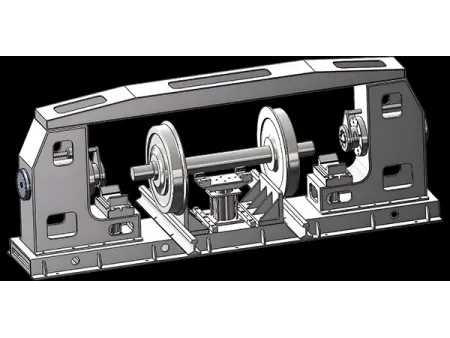

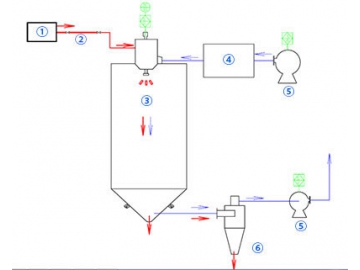

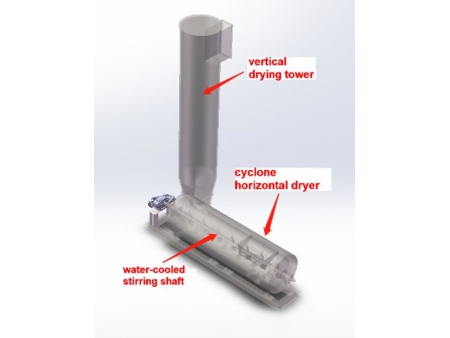

The MCMB, carried over from upstream processes and still containing wash oil, is fed continuously and in controlled amounts into a sealed rotary tray dryer using a dedicated anti-bridging feeder. Heat and mass transfer occur as the material moves through the dryer, allowing for gradual moisture removal. Once dried, the product exits through the bottom outlet and is transferred to a separate cooling unit before packaging. Vapors released from the wash oil are directed through a dedicated exhaust port, pass through a dust collection unit, and are then cooled for oil recovery. Non-condensable gases are safely vented. The entire system is fully sealed from ambient air and includes additional safety measures to ensure stable and secure operation throughout the drying cycle.

- The MCMB drying system operates continuously through conduction-based heat transfer. Since no air is introduced during the process and exhaust volume is minimal, thermal efficiency can exceed 85%, making it highly energy efficient.

- Material loss is negligible, and the environment remains clean. As the product moves downward through the dryer, from wet to dry, the extremely low exhaust velocity (around 0.1 m/s) prevents dust from becoming airborne or escaping with the exhaust stream.

- The entire drying and cooling line is sealed, allowing for complete solvent recovery. Equipped with a specially designed dust collection unit, the drying system can recover more than 99.9% of the solvent from the exhaust.

- By preventing any air from entering the dryer, the risk of combustion during the drying process is eliminated. This is critical when handling MCMB, which is highly flammable upon contact with oxygen at elevated temperatures.

- Drying conditions can be adjusted by controlling rotation speed, thermal oil flow and temperature, rake blade’s angle, feed rate, and the number of active drying trays. This flexibility ensures consistent product quality.

- Due to the poor flowability of wet MCMB, conventional feeders often cause bridging. Based on years of engineering experience, we developed a special anti-bridging dosing feeder to ensure smooth, continuous material input.

- Since the material requires a residence time of over two hours, the internal layout of the tray dryer has been modified to maintain stable flow while allowing extended processing.

- A specially engineered rake blade mechanism prevents the product from sticking to the tray surfaces, allowing for steady movement and even heat distribution throughout the drying cycle.