Metal Coating

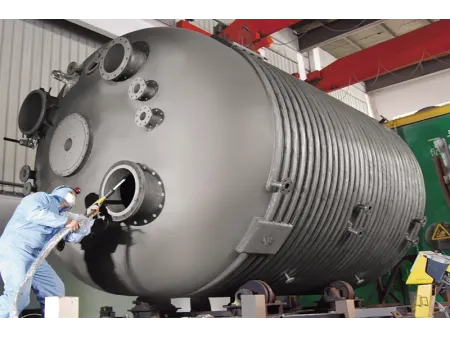

Applying a layer of coating onto metal surfaces is an important anti-corrosion method in metal processing, and is easy to realize some special functions needed. An excellent protective coating layer can maintain a flat, unchanged state for long periods of time. It acts as a barrier for inhibiting external impurities from corroding the underlying metals. Various special functions can be realized through insulation paint, heat conduction lacquer, heat insulation paint, non-stick paint and other metal coatings. Metal coating is widely used in electronics, appliances, nonstick pans and many other metal products. Additionally, the application of colored polyester coatings, fluorocarbon paints, and other coatings can achieve colorful decorative effects on the metal service. You will see this type of metal coating on:

- Metal interior decorative panels

- Metal advertisement billboards

- Metal suspended ceiling

- Aluminum composite panels for building curtain wall

- Furniture metal finish

Senr's solution

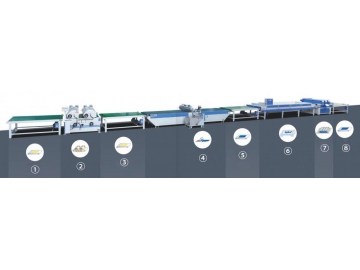

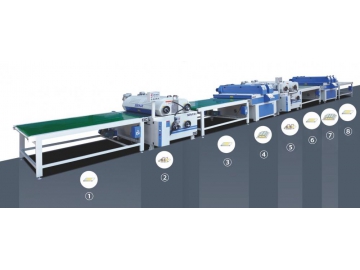

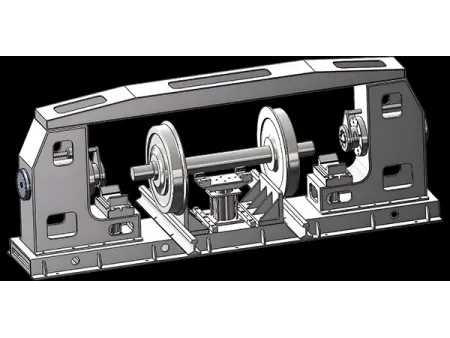

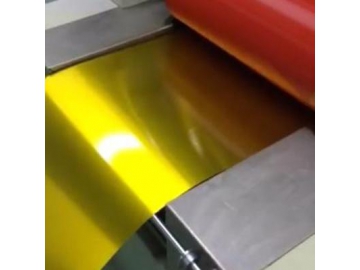

Roller coating is the most common metal coating process. Depending on different requirements for products, such as coating thickness, roller coating can be performed on the metal surface one or more times. The whole roller coating process is automatically controlled by computer and allows more even coating thickness than that of manual spray coating, which is capable of reaching more stringent testing requirements. According to the customer's production needs, Senr can provide single roller, dual roller, three roller coaters for metal roll coating, which can adapt to a variety of metals such as aluminum, copper, tinplate, stainless steel, and magnesium. If you have higher requirement on coating flatness, we are also capable of offering the roller coater with a laser roller as the coating roller.

High gloss effect of decorative iron plate painting after curtain coated with UV paint

Effect of copper-nickel-zinc alloy coil after roller coated with insulation paint

Recommended coating equipment

- Single Roller Coater (Roll Coater, Coating Machine)

- Dual Roller Coater

- Three Roller Roll Coater

Recommended drying equipment

- Tunnel Fluid Bed Coating Drying Oven (Infrared Heating)